AutomatedBuildings.com

Article - July 2002

[Home Page] |

[an error occurred while processing this directive]

(Click Message to Learn More) |

|

|

Of the

hundreds-of-thousands of intelligent devices produced by manufacturers in

Building Management System (BMS) space, many incompatibilities exist

between these devices and their "device specific" communication

protocols. |

Jonathan

Buckley,

VP

Marketing and Business Development

jbuckley@netbrowser.com

NetBrowser Communications NetBrowser

has pioneered and patented an enterprise monitoring software suite,

e-Guardian®, for what it calls The Zero Layer™, or the facility

foundations layer upon which critical IT systems depend. NetBrowser’s

Fortune 1000 customer base has plenty of stories of how they avoided

disasters and boost uptime using this new technology. |

Today's

Building Management Systems (BMS) have a heritage in industrial automation and

controls. The nature of building and industrial automation requirements is that

it requires a constant streaming of data from the equipment level to back to a

central control computer and often times over distances and through environments

not well suited for what is now standard (non-industrial networking), Ethernet

cabling. Furthermore, the constant streaming of data on the larger corporate

network was rightly seen as a burdensome bandwidth overhead. The typically long

cable runs through environmentally hostile factory environments make for a

difficult application of the corporate Ethernet. Several other factors existed

when BMS technology was developed years ago:

-

TCP-IP over Ethernet

was not a de facto networking standard

-

Fast Ethernet

(100BaseT) did not exist so bandwidth was scarcer

-

Ethernet was

considered non-deterministic before the advent of economical Ethernet

switches - risk of packet collisions created reliability worries when micro

managing critical manufacturing equipment.

-

Ethernet cabling was

relatively expensive

Because of these

conditions during the development of industrial automation technologies, such

systems, and their BMS cousins, tend to require proprietary communication wiring

and protocol allowing for a dedicated, shielded network. Two protocol standards,

each normally requiring their own dedicated wiring plant, emerged out of this

automation-heritage marketplace:

-

LonWorks®, a

standard marketed by Echelon Corporation

-

BACnet®, a open

standard developed under the auspices of the American Society of Heating,

Refrigerating and Air-Conditioning Engineers (ASHRAE)

These standards have

subsequently been adopted, but because of the limitations imposed by the

technology at that time, BMS implementations have largely been localized,

resulting in islands of information that are not easily aggregated, analyzed,

and utilized. Therefore, the potential "gold mine" of facility

intelligence within the facility assets that could support customers, under

constant pressure to reduce operating costs and better understand how to improve

overall return on assets, is simply not readily available.

In both factory and

building automation, the activity of management and control is largely still a

local one. Usually the plant or building is substantial enough in size that to

provide a dedicated network to carry the constant stream of data to a central

console and a round-the-clock engineering crew to manage operations offers few

challenges.

Of the

hundreds-of-thousands of intelligent devices produced by manufacturers in

Building Management System (BMS) space, many incompatibilities exist between

these devices and their "device specific" communication protocols.

This is even true when the products are from the same vendor. Moreover, the

various proprietary systems require expensive unreliable and slow phone links

(usually dialup) for each subsystem. Lastly, each product line requires

different control stations, which increases maintenance costs and technical

complexity.

Challenges that BMS

Vendors Face

Furthermore, the current

BMS vendors have always been behind the technology curve. Widely used standards

and technologies have barely begun to penetrate the BMS product offerings.

Standards like TCP/IP, XML, and RDBMS' have been commonly used in commercial

applications for over 20 years, but the current BMS vendors haven't embraced

these standards. Instead, each BMS vendor develops "home-grown"

solutions for connectivity, data management and data analysis. More recent

technologies like Java, web-based connectivity, e-mail, etc. have yet to appear

in current BMS product offerings. Their reluctance to embrace current standards

has complicated facility management operations and greatly increased ongoing

maintenance costs to building owners and operators.

[an error occurred while processing this directive]BMS

vendors relish the current state of affairs. By imposing proprietary protocols

and technologies, they, in effect, lock their customer into a steady revenue

stream for maintenance, upgrades and service. Because the difficulty of

interconnecting the vast number of embedded facility systems seems so great,

customers tolerate the current state of affairs. BMS vendors continue to exploit

the revenue stream, and their customers are not offered better options.

One might conclude that

the BMS manufacturers have consciously created (and maintained) this environment

to effectively limit their customer's choices to "proprietary"

building automation solutions. This conclusion is supported by the fact that

these same incompatibilities exist in products supplied by the same manufacturer

within a single facility. It is typical to find multiple control stations

supporting building automation tasks operating as standalone control points,

each control point requiring manual oversight. This "proprietary"

scenario is further exacerbated when a building owner/operator has multiple

facilities. Furthermore, these proprietary systems simply don't scale very well.

Handling multiple sites becomes ever more complex and costly. Finally, remote

management is almost non-existent with these proprietary solutions. They were

designed to accommodate only the local building in which they're resident. There

is simply no way to efficiently collect and aggregate data to provide meaningful

decision support information.

In response to the new

market demands for remote access to the systems, at best, BMS companies are now

making an attempt at modernizing their systems by adding IP gateways at each

site, for either a web "enabled" access to the system or to link

multiple sites via the Ethernet network. More common are the use of a system

modem and an analog phone line for the system to dial out alarms and to allow

user dial-ins for trending and remote diagnosis. This is troublesome because:

-

IP Gateways present a

single point of failure on a system guarding mission critical

equipment.

-

IP Gateways are

largely Microsoft Windows® based PCs which creates issues of network

security and system stability compared to UNIX derivative solutions.

-

BMS still constantly

streams bulky data across the network, which is not necessarily a problem

over the LAN, but causes issues over the WAN.

-

Modem notification

will never be as secure or reliable as notification via the network.

Despite the New Internet

Economy demands on BMS companies, we find that the older technology building

management systems have only made simple extensions into the task of monitoring

the mission critical data environments.

The Resulting

Inefficient Facilities System Environment

The technology

limitations, the inefficient and redundant infrastructure, and the required

"manual" intervention result in an inefficient systems environment.

Two examples will illustrate this: (a) dial-up communications (b) data

collection process (rounds and readings, data trending, and diagnostics).

[an error occurred while processing this directive]Traditional

BMS systems are equipped with dial-up connections as the "de facto"

standard for communications. These workstation-centric, modem-oriented systems

have many limitations. To begin with, they are expensive to install, maintain,

and operate. In addition, the traditional controller and field gear networks

can't route traffic over the Internet, so each device requires dedicated dial-up

communications. Furthermore, current BMS vendors do not provide coherent systems

to collect data. Lastly, the workstation-centric systems are intrinsically

limited in the number and type of connections they support. In summary,

traditional dial-up data collection, cleansing and conditioning takes too long

and cost far too much to install and operate for each site.

Aside from the

limitations of dial-up connections, the traditional data collection process is

inefficient in rounds and readings, data trending, and diagnostics. First of

all, rounds and readings are among the most common tasks and among the most

labor intensive. Facilities personnel carry a clipboard or personal digital

assistant (PDA) to each device, recording important measurements as they go. On

completion of the rounds and readings tour, the facility personnel manually

upload the readings to a laptop or desktop computer and manually initiate data

upload via modem to the analysis workstation. Other facilities personnel

manually capture and load the rounds and readings data into the collection

database and manually generate exception and analysis reports. Because these

processes are so labor intensive and costly, rounds and readings are performed

only for the most critical environments, such as data centers, manufacturing

plants and semiconductor fabrication facilities. In addition, the exception and

analysis reports that may be produced do not form the basis of closed-loop

facilities control; they only provide value in identifying the largest fires to

fight.

Second, data trending is

similar to rounds and readings, but often exhibits greater automation. Facility

personnel usually initiate data collection with manual procedures to capture

readings stored in controllers. After collecting the data over dial-up modems,

the facilities personnel manually load the data into the analysis database, and

then manually perform exception and analysis reporting. As for rounds and

readings, the trending functions serve mainly to identify problems for

firefighting.

Third, diagnostics, by

definition, provide the basis for problem resolution and other firefighting

activities. Facility personnel customarily use laptop computers to collect

metrics. They manually upload data sets to support specialists. The specialists

manually perform the data loading, cleansing, purification and analysis

functions, using manually generated reports. Again, the labor intensity is high,

so time rarely exists to take predictive action, only problem remediation.

New

Technology to Overcome BMS Shortfalls

New

Technology to Overcome BMS Shortfalls

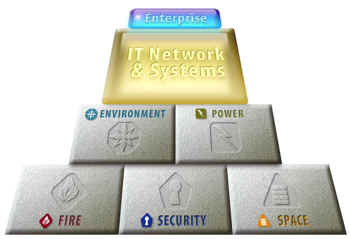

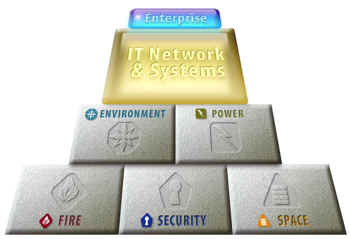

With the new demands of

the distributed mission critical facility marketplace, companies must look into

solutions that can unify these disparate data islands while being mindful of

bandwidth overhead, network security, scalability and system stability. A

starting point is in recognizing the need to interconnect this critical

facilities foundational layer that we refer to as the Zero Layer. This

foundational layer includes power, environmental, fire safety, space, and

physical security machinery, such as uninterruptible power supplies (UPS), air

conditioning units, fire panel, and other environmental equipment. Study after

study shows than somewhere between 30% and 50% of the failure in the IT

network and systems has a root cause in the Zero Layer facilities foundational

inputs.

New tools such as

NetBrowser's e-Guardian® are now coming to the market to begin to address this

forgotten piece of the facilities foundation layer. With these solutions, it is

finally possible to manage all the facilities as a single unified network. These

solutions are equipped with an Agent code that directly connects to the facility

device using the manufacturers' own code and then directly connects to the IP

network through the employment of a common serial to Ethernet appliance. The

facility machinery, such as a generator, simply becomes a node on the corporate

network. Using this patented process, the Agent sends a once-per-minute

compressed packet to the server which resides somewhere on the WAN or the

Internet. The workload of monitoring each second stays local to the machine so

data does not need to stream over the network.

With solutions such as

e-Guardian®, by simply plugging an Agent into the device and the existing

network a company can economically monitor all distributed critical sites

through one web portal. There are no "IP-Gateways" creating single

points of failure and driving up expense when a remote facility needs to be

brought online. Using TCP-IP and the latest encryption technologies on a Linux

operating system, it provides the most reliable, secure and stable monitoring

technology in the world. These solutions do not eliminate the use of a BMS for

its intended purpose - local control. Instead, it focuses on its intended

purpose - to make sure the company receives the most robust critical facilities

information within the Zero Layer as reliably and as quickly as possible so that

its network does not skip a beat.

Built on new era

architectures that directly monitor and predict the health and well being of the

foundational layer and link them to the rest of the distributed IT network and

systems, these tools now hold promise to provide the same visibility into the IT

enterprise as the CFO would expect of his/her financial system.

Requirements in New

Technology Evaluation

What are some of the

requirements when evaluating solutions to overcome the BMS shortfalls and better

unlock the value in this facilities foundational layer by managing as a single

unified network?

|

Make

sure your solution…

|

So

that…

|

|

Incorporates

software tools that provide a unified view of all the power, fire,

environmental and physical security equipment in all parts of your

enterprise

|

You

manage all of the foundational equipment in one cost effective,

integrated fashion regardless of the number of locations. IT and

Facilities can understand, without delay the status of remote site

health through one portal.

|

|

Scale

from the enterprise right down to the computer rack and back up again,

making sure that not even a Telco closet becomes a missing link in the

chain. Manage through one

portal accessible from anywhere.

|

You

cover the entire the input level of the supply chain rather than only

selective components, to reduce downtime and cost.

|

|

Connect

seamlessly to all manufacturers and types of foundational machinery

|

You

eliminate machine vendor dependency, save money, and have one view of

all vendors, types and locations of equipment.

|

|

Allow

flexibility in accessing the system data

|

If

IT and Facilities are to unite interests, you must have the flexibility

to access the system and its data from anywhere, in various formats,

using a simple browser, MS Excel™, or wireless PDAs.

|

|

Provide

the highest level of data security

|

The

corporate IT security department must be at ease so there must be no

dependency on modems, security holes in the firewalls, or any users

coming from outside the firewall to access information

|

|

Work

without hogging much bandwidth on your corporate network

|

You

avoid additional cost of dedicated data lines and conflicts with IT over

traffic concerns. Be able to grow the solution without worries of future

network growth needs.

|

|

Provide

for the same level of N+1 redundancy you expect from critical network

systems

|

You

get a dependable monitoring solution that monitors and safeguards your

data, no matter what happens.

|

|

Provide

for ease of installation and maintenance

|

The

IT department can understand, support and help install the system

without costly outside system integration specialists.

|

In conclusion, proactive

managing of your facilities as one, complete enterprise network can help

businesses avoid the costly outages and downtime associated with unplanned

failure in their facilities machinery. Getting to this information is a

challenging task that few companies ever accomplish, especially given the

external pressures and implementation obstacles today. As companies seek

solutions to automate their entire infrastructure, they must look holistically

at the key requirements and leverage the benefits of new technologies coming to

the market over the next few years.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]

New

Technology to Overcome BMS Shortfalls

New

Technology to Overcome BMS Shortfalls