June 2004

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

June 2004 |

[an error occurred while processing this directive] |

|

This is the third of 9 articles on VBHQ where we introduce the building, the cost benefit for interoperability and the cost benefit gained from the procurement technique achievable with open systems and choice.

May's article

Intelligent Intelligent Building, VBHQ Part 1

|

Paul D.J. Mason, C.E.O. |

VBHQ, virtual building headquarters is a complete building design. The purpose of this 11,000 m2 building is to compare the costs of different systems. The first cost comparison with the model is between traditional conventional controls and an integrated solution using the LonMark System.

|

[an error occurred while processing this directive] |

Part 1 introduced the building, introduced the two cost saving areas of procurement and open system commodity product (hardware and software) and an overview of the cost comparison itself.

The first part demonstrated the prices for the whole M & E works for this building to be $12,845,000 traditional controls ($1,004.36 /m2). This compares with $12,330,000 and $964.74 /m2 for the open system option using the LonMark System.

This 118,402 ft2 headquarters building therefore has a 4% saving or $515,000. These prices are for works in London, UK for a quality office specification and to London codes. The detail of the building cost plan can be downloaded from www.lonmark.org/solution/building.htm.

The cost differences are extracted for you here for our focus in this month's issue. The cost differences include the elements BMS controls, invertors and such plant, lighting control, fire alarm and fire alarm wiring, CCTV, network integrator and the various forms of preliminaries. The P.A. system is not included or integrated, although it could be!

The costing was collected and checked over the year 2002/03, the data was presented at the Building Performance conference and exhibition in October 2003. The data was then collected up and distributed at the ASHRAE conference and exhibition in January 2004. The data was collected directly from the industry and cross checked for veracity by the cost consultants Turner and Townsend Group. The rates used were verified with the large database compiled over many projects from many years by the T&T Group.

The equipment used for the traditional conventional option was TREND BMS used some SONTAY, BELIMO, LANDIS & STAEFA, DANFOSS INVERTERS, ECS LIGHTING, GENT FIRE, ACTIONAIR FIRE DAMPERS, LENEL ON-GUARD SECURITY & CCTV by ABB, WANDSWOTH DISABLED PERSONS ALARM.

The Open System used TAC, HONEYWELL, and used some SONTAY, BELIMO, LANDIS & STAEFA, DANFOSS INVERTERS, SMART, ECHELON, and IMAGE OSS2000, ECS PHILIPS LIGHTING, ZYTRON FIRE, ACTIONAIR FIRE DAMPERS, KABA SECURITY & CCTV by ABB, WANDSWOTH DISABLED PERSONS ALARM.

You may note there is a $1,000 dollar difference in this extract due to some rounding errors.

Please use the downloads from www.lonmark.org/solution/building.htm as the more exact comparison model.

as

opposed to

as

opposed to  is the

basis the saving that gave us over $500,000 back to the project. The make up of

this number is $183k on the BMS including the LON Network Integrator, £48k on

lighting control, $178k on fire alarm, -$10k on security and $117k with respect

to the project preliminaries.

is the

basis the saving that gave us over $500,000 back to the project. The make up of

this number is $183k on the BMS including the LON Network Integrator, £48k on

lighting control, $178k on fire alarm, -$10k on security and $117k with respect

to the project preliminaries.

The BMS saving is achieved through the choice of products each with the same LonMark interoperability functions, also the efficiency in wiring adds some and using intelligent equipment thereby avoiding motor control centres and taking the benefit of truly distributed control functionality. The TREND system used in the comparison as the conventional system is a 20% market share player and a leader in standalone DDC BMS in the UK and has been over the last 20 years or so.

[an error occurred while processing this directive] The lighting saving has a little to do with the terminal equipment and choice, it has a lot to do with virtually entirely piggy-backing off the BMS network arrangements. The same backbone and routers and the same network cable on the floor all add to this saving.

In this design the Zytron Fire alarm provides the PIR functionality and innovatively the emergency lighting through white LED built into the multi-function unit provided by Zytron. The Zytron product is from a small UK company. The head is a significant value added product suitable for mass production maybe 5 to 6 times the cost of the current non-intelligent heads. As can be seen the whole system cost is way less than traditional BWP commend all fire manufacturers to get into the business and give up their unique panel designs and lock-in maintenance contracts. If there service network is so good then maintaining the whole system is a real possibility. These intelligent heads can do one head, one room up to major buildings; this strategy will break the current overcharging that goes on the conventional market products. The major saving here is the Fire Alarm system, some $178k. This system is entirely to code. The opportunity in the US is limited as more conservative regimes exist; there is a great business opportunity here for many many people. A quality multi-function head on fire rated systems makes good economic sense.

For many of the reasons that fire systems cost too much so do security systems. There are fewer products available to compete currently and so for now the systems cost much the same. There is a need to make best use of modern networks and memory and design. Fundamentally there is a difference in that this system does need database management and distribution of that data to enable the access devices to work. Also the digital video system and interoperation of those cameras with other network devices remain equal cost.

The fifth saving opportunity is the preliminaries. This amounts to $117k and is partly a natural benefit of the other issues costing less and partly making proper, appropriate good use of distributed technologies but also there is a benefit from having the Network Integrator (NI) which I recommend to each project. The NI is employed by the Main Contractor and not by any of the sub-contractors. The benefit of this strategy is more about certainty and risk management, the mechanical and electrical sub-contractors supply and install, providing product warranty. No application software by the sub-contractors so this risk is taken away from these contracts. The main contractor employs the Network Integrator who carries out all the application software and supplies and installs the headend and the active network equipment much like an ICT professional.

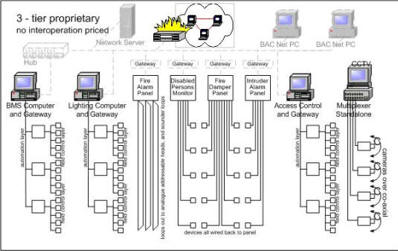

The drawing following is an example of the schematic used to build up the points list for the virtual building headquarters.

Some points gained over the 10 years of specifying these open systems include:

employ a Network Integrator direct to the main contractor, let the mechanical sub-contract employ a systems integrator for the e-to-m, let the electrical do as many cables as possible by design as proximate to the modular plant as possible, Network Integrator does all the application software and sorts out the database;

ensure no software whatsoever is bought from the mechanical and electrical sub-contracts, these sub-contracts provide product warranty on all the pre-programmed controllers, all design on the software is factory programmed or by the Network Integrator;

the need for certified interoperability at the product level (LonMark);

always use standard components as much as possible throughout (cables, connectors, active components, hubs, switches and the like);

use the biggest bandwidth backbone system you can afford ( in whole cost terms this infrastructure cost is miniscule ) ( one finds cost consultants and contractors always cutting this cost, incorrectly );

a 4-way splitter hub in each riser with one way connecting through a LON/IP router is highly recommended the other hub-ways maybe IP cameras or laptop maintenance connections or future IP connections or access database connections; the LON side connects to a ring on the floor or in the plant room;

set aside the head-end middle-ware / large software to a provisional sum for procurement by the facilities manager or the end-user team; supply and install web page monitoring only for viewing by web-browsers only which is within the contract at the minimum cost;

for example on web pages use IE and go to www.48warwickst.com and after downloading your plug-in go in on the login using guest; this was a BWP project finished in year 2001 and presented at LonWorld in Frankfurt October 2001 by the The Crown Estate and the Network Integrator Accurro and BWP plc.;

further, it is always important to modularise all plant elements as much as possible, create a plug and go set-up such that air handlers, chillers, boilers or cooling towers etcetera all come complete with added value components i.e. the plant works out of the box e.g. network connects to the variable speed drives on Grundfos e-pumps;

design plant rooms without motor control centres or large centralised panels, use the distributed controls / network controls to the max; see 1. power to be as close to plant as possible, see 9. include plant on skids and as inclusive of all components as possible; these things are completely enabled by interoperability open systems.

[an error occurred while processing this directive]

The download resources at LonMark International are:-

1. The building specification and sample pictures

2. The full cost plan and summary VBHQ introduction

3. All the drawings, 26 number, (17 x A3 and 9 x A4)

Go to www.LonMark.org and follow the VBHQ

motif

The programme we have for you will run as follows :-

1. April "Intro"

2. May "VBHQ part 1"

3. June "VBHQ part 2"

4. July "LonMark International" and the "LonMark System"

5. August "Open Systems Standards"

6. September "Procurement Advice"

7. October "Everyone Wins"

8. November "Consultants Design Notes and Openness is Safer"

9. December "Case Study Notes for Consultants"

About the Author

Paul D.J. Mason B.Eng (Hons), C.E.O. at BWP plc who are based in London and the

East Anglia region United Kingdom. BWP have an affiliate office, DWP, in Paris,

France. BWP is a niche high quality building services consulting engineering

design service company and specialist in "green" engineering. BWP like

to think of themselves in their sector/region of the UK construction industry as

a BMW in a motor car metaphor comparison. BWP currently employ 47 people. Paul

(45) has a career encompassing Marine Engineering Royal Navy, the Property

Services Agency of the UK Department of Environment, University as a mature

student, and since 1989, with 2 private sector building services design

companies "CJP" and since 1997 "BWP". Since 1999 BWP

primarily specify LonMark and LonWorks Technology.

Paul is currently chairman of LonUsers United Kingdom and the task group leader Spring 2002 to Spring 2004 of the LonMark International "EuroTaG", the group with the duty to provide marketing planning advice in Europe to the LonMark International board. BWP are members of LonUsers UK, Associate members of LonMark International, the Intelligent Building Group, the British Council of Offices, Building Services Research and Information Association, Chartered Institute of Building Services Engineers and the Association of Consulting Engineers. Paul is an invited Contributing Editor through 2004 with www.automatedbuildings.com.

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]