June 2010

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

June 2010 |

[an error occurred while processing this directive] |

|

|

Jim Sinopoli PE, RCDD, LEED AP |

Measurement

and verification (M&V) sounds so simple. After all, how difficult can it be to

calculate energy savings by measuring energy usage before and after energy

conservation measures (ECM) are implemented? The reality is very different. M&V

is a methodical, scientific process which leads to the best available metrics

for energy conservation measures and in turn affects financial transactions and

other issues related to energy and water use. Some examples of financial effects

would be energy performance contracting where the ESCO is paid based on verified

energy savings; carbon emission trading where the emissions are the focus of a

financial transaction; and even the piloting of a limited ECM (such as a

lighting retrofit) where the result of the pilot is used to determine the

building owner’s Return on Investment (ROI) and whether or not the pilot is

extended to other spaces or buildings.

Measurement

and verification (M&V) sounds so simple. After all, how difficult can it be to

calculate energy savings by measuring energy usage before and after energy

conservation measures (ECM) are implemented? The reality is very different. M&V

is a methodical, scientific process which leads to the best available metrics

for energy conservation measures and in turn affects financial transactions and

other issues related to energy and water use. Some examples of financial effects

would be energy performance contracting where the ESCO is paid based on verified

energy savings; carbon emission trading where the emissions are the focus of a

financial transaction; and even the piloting of a limited ECM (such as a

lighting retrofit) where the result of the pilot is used to determine the

building owner’s Return on Investment (ROI) and whether or not the pilot is

extended to other spaces or buildings.

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

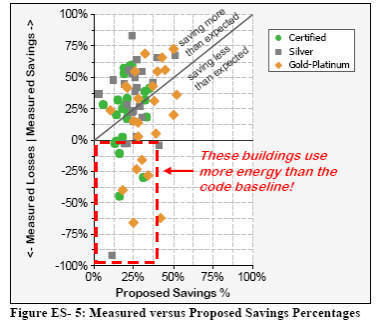

As critical as M&V is it is often undervalued and

misunderstood. Here’s a tidbit to illustrate the point: In 2008, the New

Buildings Institute issued a report on the energy performance of LEED-NC

certified buildings. Their sample pool was 522 buildings. Only 121

buildings or 22% of the buildings were able to provide at least one full year of

measured post-occupancy energy usage data. On top of that was the

finding that approximately 50% exceeded the design expectations but fully 50%

did not meet design expectations with a portion of the buildings performing

worse than the ASHRAE baseline. One of the changes incorporated in LEED

Version 3 is the re-weighting of measurement and verification from 1 point to 3

points and the requirement to provide a process for corrective action if the M&V

plan shows energy savings are not being achieved.

For those not familiar with M&V there can be confusion between commissioning and

M&V. While these activities are closely related, they are not the same and are

performed by different professionals. Commissioning essentially addresses if the

equipment was properly installed and whether the equipment and systems are

functionally operating according to the intent of the design. M&V is the process

of accurately measuring and verifying energy and water savings. With M&V all the

estimates, energy modeling, simulations, design intentions and spreadsheet

calculations are gone - what is left is the unadorned reality of the ECM’s

effect. M&V answers the questions “Did we get the results we thought we were

going to get with the ECM?” and “Is the ECM financially viable?”

What follows is a broad overview of M&V, the methodology for calculating energy

savings, elements of an M&V plan, use of metering and M&V costs.

M&V Overview

The International Performance Measurement and Verification Protocol (IPMVP)

govern M&V activities. The Efficiency Valuation Organization (EVO) creates

measurement and verification tools including those based on IPMVP. The IPMVP has

developed four M&V options to address different situations of energy use and

varying techniques to deal with each of the scenarios:

Option A – Partially Measured Retrofit Isolation – These are specific ECMs, such as a lighting retrofit for a specific floor or space, where partial measurements may provide adequate accuracy. For example, we may only be interested in the electricity savings of a light retrofit in which case we may periodically measure the power draw of the lighting circuit and calculate energy savings on that one measure. Our ECM “boundary” is just electricity saved. We know however that reducing the power demand of the lighting also reduces the heat generated, therefore decreases the need for cooling which is additional energy savings. We could widen the boundary of the ECM to electricity and cooling reductions by reasonably stipulating the cooling reductions rather than measuring them. With stipulations one has to take into account possible errors and what that may mean for the accuracy of energy savings.

Option B – Retrofit Isolation – This option is similar to Option A, but only uses measurements, no stipulations. This option may cost more because more is being measured but provides more accurate results. Most ECMs would be covered or use Option B. An example would be replacing an older boiler with a new more efficient boiler where the boundary of the ECM and the measurements are exclusively focused on the boiler’s fuel systems.

Option C – Whole Building – In this option ECMs are addressed collectively, not individually or in isolation. This option works best when the projected savings is significant or when ECMs interact or affect other ECMs. For example, a set of ECMs for one building encompassing a lighting retrofit, HVAC upgrades, plug load control, building envelope and a public awareness initiative. The boundary for the ECMs would be the main electrical and natural gas consumption. The time period to measure energy savings for Option C is typically in years as opposed to months, therefore adjustment to energy calculations such as weather and occupancy become significant.

Option D – Calibrated Simulation – This option is similar to Option C in that it addresses the whole building; however it deals with buildings with no baseline data. Software simulation models are used to predict energy usage either for the base year, the post-retrofit condition or both. An example would the deployment of ECMs in a building that is part of a larger campus that does not have an individual building meter.

Energy Savings Calculations

and Adjustments

Energy savings are essentially base year energy use, minus

post-retrofit energy use, with adjustments. Base year and post-retrofit energy

use is supported by hard data from calibrated meters and sensors. It’s the

adjustments that "normalize” the base year and post-retrofit energy use into the

same set of conditions.

Adjustments are typically used to restate the base year energy use. Some

adjustments are anticipated, such as weather or occupancy, while others are

unforeseen such as a change in equipment operations. Other factors that could

affect energy use include occupant acceptance of the ECM, equipment

deterioration, the design and implementation of the ECM, user demand for

services, schedules, etc. The goal of this exercise is to obtain reliable and

accurate data on the energy savings. Unknown variables and variances or “noise

levels” of the data result in less accurate, less reliable data, so to a large

extent, the effort in calculating savings is focused on reducing and addressing

uncertainty. In addition, the M&V approach has to balance the cost with the

uncertainty; for instance, would you spend $20,000 to improve the accuracy of

the overall cost savings by $10,000? Probably not.

[an error occurred while processing this directive]

Metering, Sensors and the BAS

Metering is obviously a key component to measurement of energy usage.

Building meters should be calibrated and should replicate the method of the

meter being provided by the local utility. The “energy/pulse” meters common in

buildings should be calibrated with the utility’s revenue grade meter, as well

as calibration standards and procedures developed by the National Institute of

Standards and Technology. Some meters are self-calibrating. If, for example, the

utility meter is calculating peak demand with a 10 minute sliding window, the

building equipment should do the same. BTU meters and sensors for temperature,

humidity, flow, pressure, light levels and equipment runtime may also need to

obtain data on the conditions of the ECM and make adjustments to the energy

savings.

Eventually all the meters and sensors are tied together in a building automation

system that will collect the data using an embedded or third-party energy

management software application to analyze and provide reports on the energy

consumption and costs.

M&V Costs

Studies by the US Department of Energy suggest that the average cost

of M&V services is in the range of 3-5% of total costs. IPMVP shows the cost to

determine the energy savings is typically less than 10% of the total energy

savings. Cost will vary by the Option used. A study by NAESCO and the US EPA

found the cost for Options B and D to be around 3-10%, Option A to be 1-5% and

Option C to be 1-3% depending if meters were already installed. Cost will vary

based on the amount of equipment, the value of energy savings, the interaction

between energy consuming systems, the level of uncertainty, the availability of

an energy management systems, etc.

The M&V Plan

A M&V plan will vary depending on not only the Option selected but

the purpose and the level of accuracy required. An M&V plan to be used as part

of a contract between a building owner and an ESCO will be different than a plan

developed by the facilities department to test a lighting retrofit ECM. Major

elements of the plan should contain:

A description of the ECM(s) and the anticipated effect

The boundaries of the ECM

Base year conditions and energy data

Proposed changes to the base year

The duration of the post-retrofit period

The set of conditions that adjustments will be applied to

The commissioning procedures for the ECM

The IPMVP Option that will be used

The analysis procedures and assumptions that will be used

The specifics of the meters that are to be used (calibration, commissioning, time periods, etc.)

The quantification of the expected accuracy of the measurement, noting factors that cannot be quantified

How results will be reported and documented

Dependencies of third-parties

The budget and resources required for the total M&V process

The astounding fact that only 22% of a sample of LEED

certified buildings have one-year of post-occupancy energy data, tells a lot

about the changes needed in building operations. We need to focus on results and

M&V is the means to that end. M&V and energy reporting must be ingrained in the

design and operation of buildings.

For more information, write us at

info@smart-buildings.com

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]