Next-Generation Building Energy Management Systems Answer The Call

|

June 2011 |

[an error occurred while processing this directive] |

| Real-time Data for Real-time Demand Management Next-Generation Building Energy Management Systems Answer The Call |

|

The

facility manager’s mandate is clear – reduce operating costs by

trimming energy use while simultaneously improving systems reliability

to ensure occupant comfort. Piece of cake, right? With the

next-generation of building energy management systems (BEMs), there’s a

much clearer and shorter path to meet this mandate.

| Articles |

| Interviews |

| Releases |

| New Products |

| Reviews |

| [an error occurred while processing this directive] |

| Editorial |

| Events |

| Sponsors |

| Site Search |

| Newsletters |

| [an error occurred while processing this directive] |

| Archives |

| Past Issues |

| Home |

| Editors |

| eDucation |

| [an error occurred while processing this directive] |

| Training |

| Links |

| Software |

| Subscribe |

| [an error occurred while processing this directive] |

By combining new sensor technologies

for real-time energy data collection, a data store and energy

diagnostics reports, these new BEMs now make it economical to access

and manage demand in real-time – in any building. How? With visibility

into the overall energy footprint via energy profiling at the source

– such as a lighting or power panel, down to the individual piece

of equipment – these BEMs reveal a facility's energy profile and allow

building staff to pinpoint energy-wasting systems or procedures.

For those working on energy

efficiency retrofits under CALgreen (CA Title 24) or the new Federal

Energy Management Program (FEMP), electricity monitoring is now an

essential – often mandatory – project requirement. Why?

Because it works to trim energy consumption.

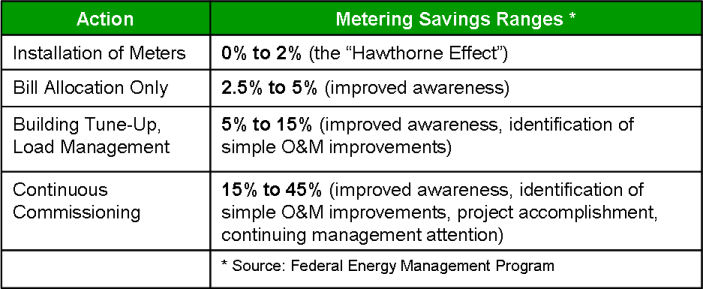

In each of these metering scenarios, time-stamped metered data is used

to measure, verify and optimize building performance. The level of

savings is related to the metering level, from simple allocation to the

tracking of building sub-systems via continuous commissioning.

In addition to the main business case – trimming energy costs – these metering scenarios can form a new, more dynamic measurement infrastructure to:

- set utility budgets for organizational units;

- develop baselines for energy savings performance contract (ESPC) negotiations

- measurement and verification for ESPCs, net metering or green leases

- identify potential retrofit projects or equipment upgrades;

- comply with new building codes for retrofits (i.e., CATitle 24, EPAact)

- promote energy use awareness for building occupants.

Getting Started with Real-Time Data to Manage Energy Consumption

The new generation of BEM systems use advanced metering technologies to

pinpoint energy savings measures for continuous improvement in a

building’s performance. Advanced metering allows building operators to

use time-stamped snapshots to profile loads; detect unnecessary use;

and test schedule or set-point changes to optimize building operations.

By aggregating energy data from

multiple sources, these systems exploit internet technologies to

provide both visualization via dashboards and analytics that let

building engineers drill down into consumption anomalies. Leveraging

these new technologies to designing a building-specific monitoring

infrastructure is indeed a balancing act.

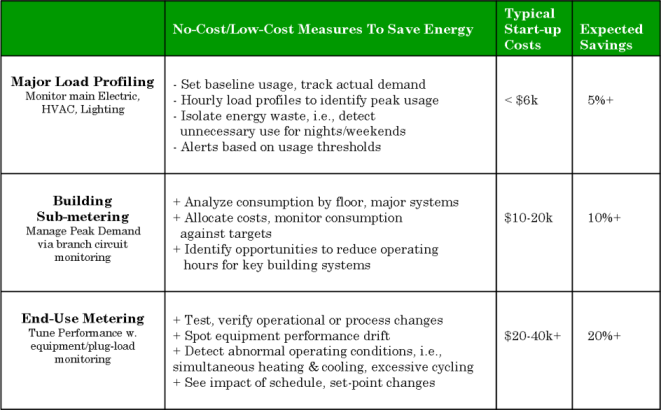

The first step is deciding what level of measurement is justified. The

key design consideration is selecting the right level of data

granularity to drive “No-Cost or Low-cost” energy efficiency measures

that suit your business/operational requirements.

Major Load Profiling To Find Opportunities, Immediately

Most customers start by monitoring major energy consuming systems – HVAC for cooling and heating, and lighting systems. This can help identify energy hogs, and also help define wasteful, time-of-day usage patterns.

With Major Load profiling, building staff can uncover the "low hanging fruit" – such as unnecessary lighting after hours or on weekends. Most customers make an immediate discovery that pinpoints waste – for example, discovering that perimeter lighting is on during the day.

Building Sub-metering To Develop Mitigation Strategies

Adding circuit measurements will provide the ability to drill down into

energy loads. This is key to identifying specific areas – floors,

lighting zones, classrooms, computer rooms – which may be consuming

excessive amounts of energy, and racking up demand charges or

time-of-day premiums.

Enhanced data collection is just the first step – it’s how the

measurements are exploited on a perpetual basis that yields lasting

energy efficiency gains. With data online, Energy Diagnostic reports

provide trends to uncover simple fixes such as eliminating simultaneous

heating an cooling (the #1 issue in commercial buildings), delaying

building warm-up/shutdown schedules to reflect occupant patterns,

switching functions to off-peak hours or adjusting the temperature of

an air-conditioning system. Any of these measures can quickly add-up to

significant savings – without significant capital investments.

A BEM uses a data store to aggregate consumption information and make

it available to slide-and-dice energy consumption patterns in new ways.

By defining a unique building hierarchy to map the data, it’s possible

to create entire new “virtual meters” to measure consumption without

additional instrumentation – in a building, for a campus or across an

entire portfolio.

[an error occurred while processing this directive]Tools

to allocate costs by building areas will help you to engage business

managers in saving energy too. At many of our sites, facilities

managers use Top Consumers reports, set energy budgets by department,

and use scoreboard displays in lobbies to help shape occupant behavior.

End-Use Metering To Fine-tune O&M Procedures

To understand a building's overall energy profile, it may make sense to monitor individual pieces of equipment, including chillers, pumps, air handlers, and other HVAC-system components. Or, use plug-load monitors to track individual appliances and office equipment. Once an accurate baseline is set, then deviations highlight opportunities for operational improvements or equipment repairs.

At one client site, the facility manager wanted to measure and verify the efficiency of a new, high efficiency transformer, so we monitor the power supplied to the transformer and the power output from the transformer. We use a virtual monitoring node to calculate the difference between the energy in and the energy out, which is the energy lost to heat. The customer tracks the energy lost to ensure that the transformer is operating up to specifications.

Another example - air handling units can get stuck in a mode where they're heating and cooling simultaneously. A monitoring system with sensors can spot the excessive cycling, allows building engineers to take immediate corrective action would immediately reduce energy waste. By identifying what's actually occurring day-by-day, piece of equipment by piece of equipment, you are likely to get an immediate payback by uncovering operational anomalies.

Example “No-Cost” Measure: Energy Dashboards Support Peak Demand Management

Peak demand mitigation, in particular, can generate immediate savings.

By supplying the time-of-day statistics for each building area or

subsystem, these BEM systems provide guidance on energy usage, match it

to utility pricing schemes, and generate alarms to help mitigate peak

demand charges.

At most of our sites, the Peak Demand dial is an important tool for

proactively managing costs – by helping clients to manage demand

charges. To align with the way most tariffs trigger demand charges,

rolling calculations are done for calculating the peak demand in

kilowatts per hour today, yesterday, the current calendar month, and

the previous calendar month.

In addition to the dashboard display, alerts can be sent via email,

text or smart phone as Peak Demand thresholds approach, allowing

building engineers to react by shedding loads to avoid additional

demand charges.

Measure Only What You Need To Manage – Meter Selection

An

advanced BEM system should have the flexibility to mix metering levels

in a building, campus or portfolio. That way you’re only investing in

sub-metering when and where it’s justified.

An

advanced BEM system should have the flexibility to mix metering levels

in a building, campus or portfolio. That way you’re only investing in

sub-metering when and where it’s justified.

In fact, we often see clients start with Major Load profiling to

uncover operational variances that can be corrected, then later add

circuit metering for key areas or systems. Today’s systems are designed

to easily add new sensors and gateways to build out a system at a pace

that matches operational needs.

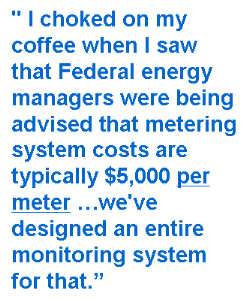

If your goal is to find waste

opportunities, design mitigation measures and then verify

results, new generation of inexpensive BEM monitoring systems can

be much less expensive than traditional submeters. You probably don’t

need expensive revenue-grade meters to figure out how to manage your

utility costs. Effective, actionable energy information is usually the

key – not accuracy. Generally, metering totals that are within

1-3% accuracy suffice for identifying and making operational changes to

trim utility bills.

With actual monitored data and a next-generation BEM system, problems that have been overlooked - often for years or decades – can be exposed and fixed via no-cost/low-cost measures. Savings can be both immediate and permanent. By carefully designing a monitoring infrastructure, you can be on your way to measure what you need to manage.

About Agilewaves

Agilewaves, Inc is a building energy management system firm based in

Silicon Valley. The Agilewaves Building Optimization System™

provides a real-time energy monitoring foundation to actively measure

electric, gas and water consumption. See details on energy efficiency,

CALgreen and FEMP projects at www.agilewaves.com/projects.

[an error occurred while processing this directive] [Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]

[Click Banner To Learn More]