|

June 2012

Article

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

What

do you need to know about industrial wireless networks?

The improved ROI of wireless – for repair and

maintenance and lower overall operating costs, as well as its

flexibility of installation and reconfiguration are the principal

drivers.

|

|

Industrial

wireless switch and sensor networks are becoming more popular in a

wide range of warehouses, factories and campuses.

Over

the last several years, developers and facility managers have

become more educated about the technology and its characteristics, and

have become very comfortable implementing wireless solutions.

Yes, we

still occasionally get the question, “is wireless secure and

can it really function in an industrial setting?”, but most questions

are now about how it will work in their own environments and how to

effectively replace wires and cables with wireless.

A

primary motivating factor behind the shift is the value, the

ROI that wireless can bring to factories, warehouses and industrial

plants.

Fig 1 - CAPTION: The Honeywell Limitless™ network

consists of

wireless limit switches which monitor position and a Limitless WDRR

Receiver that can talk to up to 14 different switches at a time.

To

ensure reliability of the wireless switch network, each switch

provides a way to ensure that the signal is actually getting through to

the monitoring receiver. In extremely RF noisy environments or those

with lots of moving equipment, the switches can be programmed to

re-transmit the signal until it gets through. The wireless receiver

monitors the quality of the signals to ensure that it is reliably

receiving the signals from each switch node. In addition, in the case

of battery powered switches, each switch provides a power monitoring

function that provides an alarm when the batteries begin to get low.

Automotive

factory managers and assembly line designers have found that

the cost of going wireless is much less than the long term,

accelerating expenses of maintaining, reconfiguring and repairing

cables.

Wireless Control for Doors and Vents

A good

example of how wireless is used is to control and monitor open

doors and vents that waste heat and air conditioning, or that are

security access points.

One such interesting application is the use of the Honeywell Limitless™

industrial wireless network to monitor the status of hangar doors at

airports.

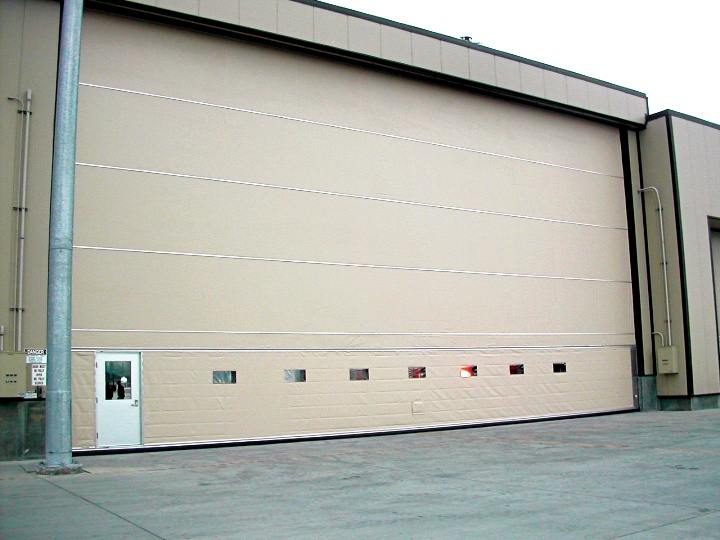

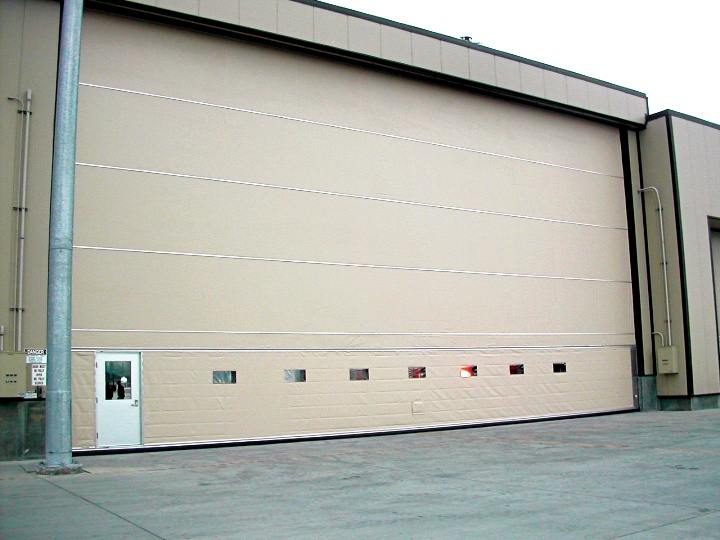

Figure 2 . CAPTION: An aircraft hangar

door with a personal cutout door at the lower left

If you have visited an airport or military facility, you will note that

large aircraft hangar doors often have small cutout doors (Figure 2)

that can be opened for access instead of raising the entire large

hanger door.

Opening the main door while the smaller door is unsecured can cause

thousands of dollars in hangar and/or aircraft damage. Because the

personal door is encased in the folding main door, getting

communication cabling and power to the personal door is a significant

engineering challenge. As these doors both move, traditional wiring

would be subject to flexing and straining, which can result in

communication failures.

The wireless network can provide information regarding the open/closed

status of the access door itself, as well as the device diagnostics. Is

the door switch functioning and transmitting? How reliable is the

signal? If the switches and battery are battery-powered, what are the

battery levels? If there is a problem, the Limitless™ wireless system

is easy to troubleshoot compared to a wired solution which can require

tearing up hundreds of feet of tarmac to find the break in the cabling.

Not only is that expensive, but the possible downtime as the runway or

traffic lane has to be closed off, further increases the overall cost.

Wireless for Industrial Yards and Transportation

An industrial plant in Illinois depends on rail track deliveries to

keep production lines moving.

For years, a hard-wired limit switch on a rail gate was responsible for

activating appropriate indicators that notified employees of a train’s

arrival. However, when the aged wired system finally failed, it was

determined that the underground conduit had disintegrated, disabling

the electrical connection to the switch. A replacement switch was

needed quickly to resume the facility’s required safety procedures.

Initial research indicated that replacement costs for a similar

hard-wired solution would require extensive trenching to replace old

wiring, as well as contractor time and fees. The total cost could

potentially reach $10K, up to 6 weeks of installation time, and

significant site disruption.

Alternatively, a wireless-enabled limit switch and monitor was found

that could be used for position sensing and presence/absence detection.

Fig 3. CAPTION: The Honeywell Limitless

switch is mounted on the gate

and an antenna cable is mounted on the plant’s railroad crossing sign.

As a train enters the gate, the switch communicates with a monitor

mounted inside the manufacturing facility, through another antenna

mounted outside the building. The monitor then activates a computer

control system which automatically activates the facility’s safety

sound and light indicators, notifying employees of a train’s presence.

The

entire wireless system was up and running in just over 6 hours, and

cost less than $1000.

There

was no wiring, conduits, clips or connectors to purchase or

install. There was no wire routing problems to solve, virtually

eliminating location and placement restrictions of the limit switch.

Going wireless has reduced maintenance costs as well. Troubleshooting

is simplified and system reliability is increased due to the

elimination of challenges that arise from switch wiring and connectors.

The switch is simpler to replace as there is no disconnecting or

re-attaching of wiring. In addition, battery costs are minimal as

batteries last up to three years due to low power draw.

One of

the industries with the highest adoption of wireless is

occurring in large manufacturing environments such as the automotive

factory floor because they operate in large buildings and are prone to

frequent reconfiguration. A major challenge in an automotive

factory, as well as in almost any industrial or manufacturing facility,

is the exposure to constantly moving and twisting components that

shorten the lifetime of cabling, as well as long wire runs. Combined

with the hazardous chemicals often found on an assembly line, cables do

not survive long and they need to be troubleshot and repaired.

Troubleshooting and replacing broken cables or connectors in a busy and

dirty factory environment is not fast or inexpensive.

Fig 4 - CAPTION: Automobile manufacturers

throughout the world are

rapidly adopting industrial wireless networks to cost-effectively

monitor and control automated assembly lines.

[an error occurred while processing this directive]Another powerful motivation is the innate

flexibility of wireless. As

assembly lines are often reconfigured as new automobile product lines

are introduced, not re-running data cables is yet another great ROI

advantage. Using a wireless network enables quick reconfiguration of

the switches and controllers as well.

Is the

new location of the control hub optimal for the new assembly

line plan? If not, just move it. Attach it where it works best, plug it

in to power, and once again you can monitor the wireless switch

network. If it’s still not right, just unplug it, move it and power it

back up.

The reduction of downtime associated with troubleshooting and repairing

an industrial wired network often more than covers the total cost of

installing a wireless network. Every minute of downtime in a busy

automotive factory can cost tens of thousands of dollars.

Troubleshooting

a wireless network is much easier and quicker than

tracking down a shorted or defective cable connection. Imagine trying

to locate and then repair the bad spot in a cable as it twists and

winds around complex machinery coated with heavy layers of paint,

grease and grime. Many plants simply give up on maintaining their

data wires, choosing instead to get rid of the old cables and make the

move to wireless. In these harsh environments, wireless

switches in sealed, protective housings can successfully function far

longer than cabling.

The

improved ROI of wireless – for repair and maintenance and lower

overall operating costs, as well as its flexibility of installation and

reconfiguration – are the principal drivers we see for the

increasing rapid acceptance of wireless into a diverse spectrum of

industrial and manufacturing environments.

More

about Honeywell’s Limitless product line including spec sheets and

videos can be found at

http://sensing.honeywell.com/index.php/ci_id/56634/la_id/1.htm

About the Author

Joseph

Citrano III is a Global Product Manager for Honeywell Sensing

and Control (S&C). In this role, Joseph is responsible for

S&C’s wireless switch and sensor product line, driving integrated

product and technology roadmaps, program vision and leading new product

introduction efforts. He develops global execution and go to market

plans, identifying potential technologies and strategic direction.

Joseph has 15 years experience in product marketing, with extensive

experience in the oil and gas, automation systems and sensing and

control industries. Joseph holds a bachelors of science degree in

chemical engineering from Rutgers University. More info about Honeywell

sensing and control can be found here www.honeywell.com/limitless

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]