|

May 2017

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

Does Building Energy Analytics

Really Work?

Although we

did not cover how building analytics could be used for improving

occupant comfort, the answer is an emphatic Yes! Additionally,

once the optimization measures are implemented, and faults in the

building are addressed, building analytics ensures that equipment

operation does not revert back to the “old ways.”

|

Derek John Mullassery,

Building Application Engineer

CopperTree

Analytics

|

Introduction

The Internet of Things (IoT) industry is

poised to grow to US$ 3.7 billion by 2020, and smart building energy

analytics applications are expected to contribute to this growth

significantly. Lawrence Berkeley National Laboratory predicts the

spending on energy efficiency programs to more than double from 2010 levels to $10.8 billion in

2025, with a possibility to grow to $16.8 billion. These numbers

are just pointers to the fact that organizations and governments are

going to increase their investments in energy efficiency projects and

applications. The Smart Energy Analytics Campaign by the US

Department of Energy is an example – this program aims to bring

building analytics into the mainstream and enable building owners to

operate and maintain their buildings more efficiently.

Can building energy analytics actually

reduce your energy consumption and operational costs? Can it improve

occupant comfort in the building leading to occupant well-being?

Project Feedback

This is a project feedback on how a major hospital in North America used CopperTree

Analytics’ Kaizen building energy analytics solution to improve

their building performance. While the results of the Kaizen

implementation included identification of several potential energy

savings opportunities, realized cost savings from energy efficiency

initiatives, and improvements in comfort & maintenance procedures,

this article focuses on just one of the major findings by CopperTree

Kaizen.

CopperTree’s Kaizen solution was deployed

in the building in October 2016. In just a matter of one day, Kaizen’s

Automated Fault Detection & Diagnostics (AFDD) engine generated

insights that pointed to faults in the building.

There are 18 large Air Handling Units (AHUs) in

the building, and Building Automation System data from these AHUs are

sent to Kaizen for continuous monitoring and analytics. Right after the

equipment Trend Log data arrived in Kaizen, Kaizen identified that the

AHU Supply Static Pressure Setpoints were not being reset. Even though

the AHUs are supplying Variable Air Volume (VAV) boxes, the variable

frequency drive supply fans were consistently running at high speeds.

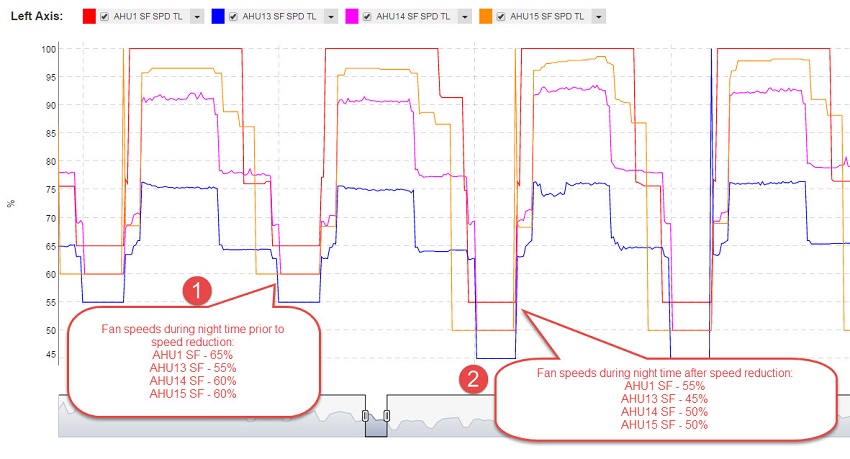

Simultaneously, another AFDD rule monitoring the

VAV boxes detected that there were long periods of the day and night

operation when the VAV boxes were supplied more air than required

(airflow above setpoint). As a first step to evaluate the system

operation, CopperTree Analytics proposed a speed reduction strategy on

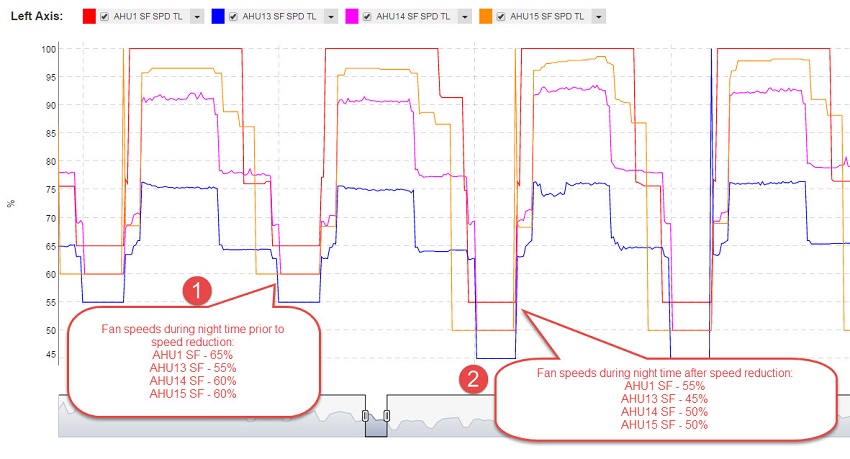

4 out of 18 AHUs in the building. The supply fan speeds were reduced

between 11 pm and 5 am to determine if the airflow requirements would

still be maintained.

Figure 1:

Comparison of Fan Speeds

Before and After Recommended

Sequence Change

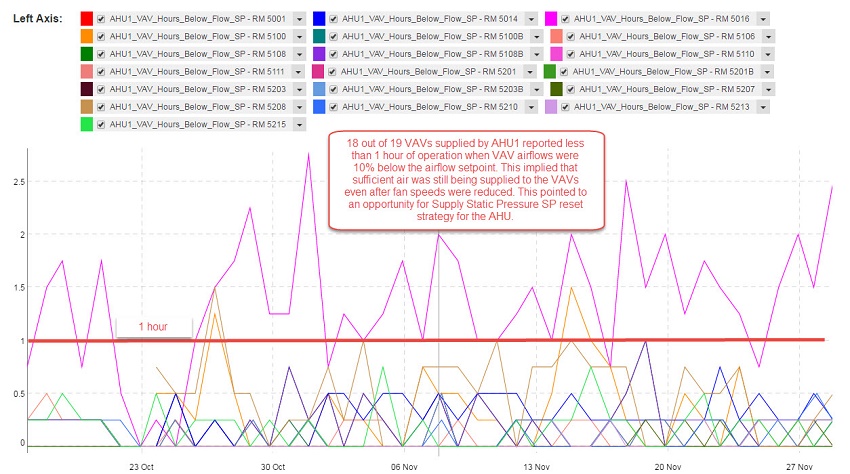

Rules were implemented on the units

to

determine the total number of hours when the VAV airflows were less

than the airflow setpoint while the fan speed reduction program was

active. The results indicated that more than 92% of the VAVs were still

being supplied enough airflow even when the fan speeds were reduced.

For instance, 18 out of 19 AHU1 VAVs were reporting less than 1 hour of

operation below airflow setpoint.

Figure 2: VAVs

Reported Sufficient Airflow

After Fan Speed Reduction

This proved

that Supply Static Pressure

Setpoint reset based on VAV demand could improve the AHU operation

while making sure that all the operating conditions were being

satisfied. The optimized program would count the number of VAVs short

of airflow, and if the total count was greater than the threshold, the

Supply Static Pressure Setpoint would be increased. This would ramp up

the supply fan speed in order to maintain the VAV airflow requirements.

The system would correct itself every 3-5 minutes, and if the VAV

dampers are seen to be closing, which is indicative of reduced need of

airflow, then the Supply Static Pressure Setpoint would be reduced. To

summarize, the optimized program implements a Supply Static Pressure

Setpoint reset strategy that continually monitors airflow requirements

of all VAV boxes supplied by the AHU.

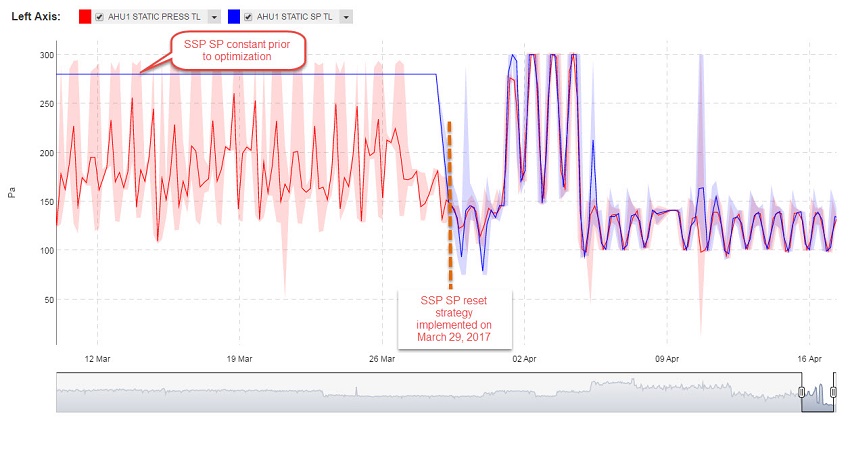

CopperTree proposed that the Supply Static

Pressure Setpoint reset strategy be implemented on AHU1 as a proof of

concept project. The operations team at the hospital agreed to

implement this strategy, and the control program was optimized on March

29, 2017.

Figure 3: Supply Static Pressure Setpoint Before

and After

Implementation of Reset Strategy

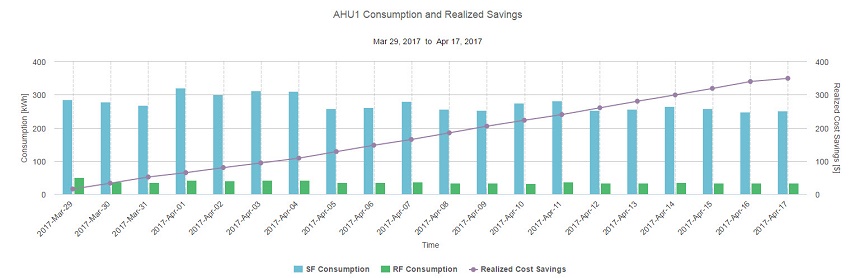

It was important to measure and verify the

results from AHU1 before optimizing the program for the remaining AHUs.

CopperTree Kaizen’s Energy and Reporting features were used for

Measurement & Verification (M&V). Energy and Cost Analysis

rules were implemented to calculate the AHU consumption and compare

post-optimization consumption with the baseline. Figure 4 below shows

the realized savings (see CUSUM Cost Savings Trend Log) for AHU1 from

the first two weeks of operation since optimization. The results

indicate that the hospital is expected to save approximately $6000 annually from just one AHU.

Figure 4: Realized Cost Savings from

Implementing Supply Static

Pressure Setpoint Reset Strategy on AHU1

After verifying the success of the project

on AHU1, the hospital is now moving ahead with the recommendation to

implement this strategy on all of the AHUs in the building. The

estimated cost savings from this measure on all the AHUs combined is

approximately $50,000 annually.

Added to this energy saving measure, CopperTree Analytics’ Kaizen has

identified several other opportunities to save energy, reduce

maintenance costs, and improve occupant comfort in the building.

Conclusion

Now, back to

the questions. Can building energy analytics reduce your energy

consumption and operational costs? Can it improve occupant comfort in

the building which in turn results in occupant well-being? Although we

did not cover how building analytics could be used for improving

occupant comfort, the answer is an emphatic Yes! Additionally,

once the optimization measures are implemented, and faults in the

building are addressed, building analytics ensures that equipment

operation does not revert back to the “old ways.”

Over and over again, our clients from around the

world are making the most of the features in CopperTree Kaizen to

improve their building performance and operation significantly.

Building energy analytics will play a very important role as we march

towards a sustainable future.

About the Author:

Derek John Mullassery is a Building

Application Engineer at CopperTree Analytics. He holds a Master’s

degree in Clean Energy Engineering from the University of British

Columbia, Vancouver and an undergraduate degree in Electrical

Engineering from India. Derek’s interests include data analytics for

building performance improvement, controls optimization, energy

management, and behavioral change programs for occupants and operators.

Additional information about CopperTree

Analytics:

Website: www.coppertreeanalytics.com

CopperTree Analytics Overview

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]