|

May 2021

Review

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

|

Digital Twin Morphing to Triplets + New Wireless Wave

As we are all trying to get our minds around the concept of

creating and using a digital twin our Contributing Editor, Nicolas gives

birth to Triplets and suggests more variants are on the way

|

Ken Sinclair

Founder, Owner, Publisher AutomatedBuildings.com

|

Digital Twin Morphing to Triplets + New Wireless Wave

As we are all trying to get our minds around the concept of

creating and using a digital twin our Contributing Editor, Nicolas gives

birth to Triplets and suggests more variants are on the way. Also featured in our April issue themed Adaptation are several articles depicting the new wireless wave

which is now hitting us with low cost easily deployed services/devices

combining the power of cell like wireless and the powerful new breed

IoT services.

Hopefully, we prepared you in our last Chapter "Adaptation" LinkedIn post here.

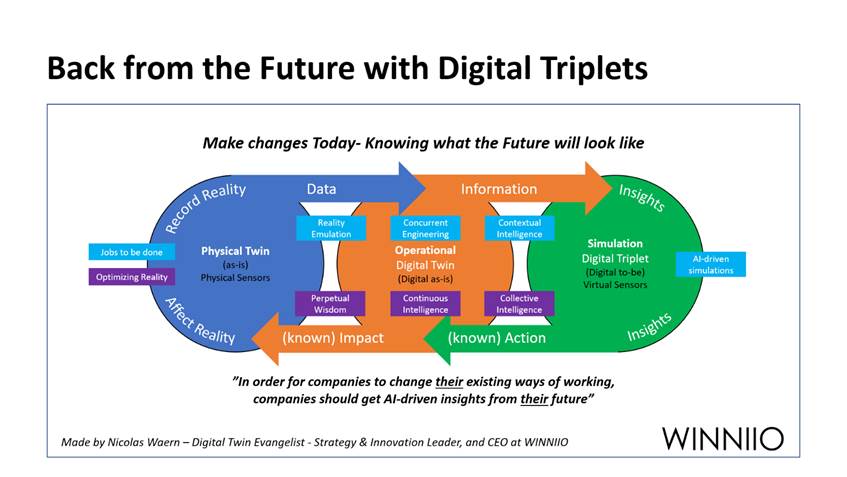

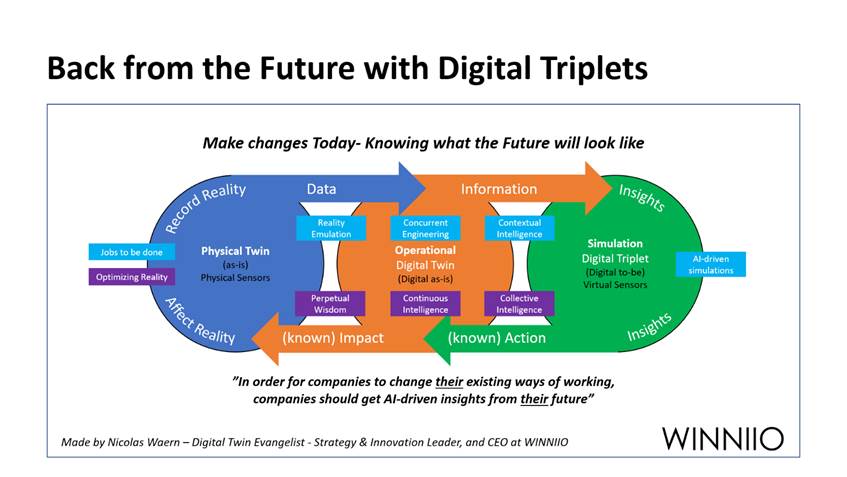

In this article Nicolas makes some great points Is there a need for Digital Triplets? Quadruplets? Siblings even? How can we adapt to a world that was, that is, and will be? How can we adapt to a future that is unknown? Nicolas Waern "The Building Whisperer"

How can we adapt to a world that was, that is, and will be? How can we

adapt to a future that is unknown? Can we make it known by utilizing

the concept of Digital Twins, and go Beyond Buildings? Can we simulate

the future, having done thousands of AI-driven simulations, and bring

the solutions back to the now, knowing what the future will look like?

Knowing that the future is already

here, only unevenly distributed. I have made it my mission to find the

tools that can distribute the future to the ones that want it the most.

Digital Twins are quite in the hype for now so thought I could stir up

some noise even more with Digital Triplets.

What started off as a joke, soon

became reality in a couple of conversations with partners and vendors

last week. I talked to legends in the Power industry having written

articles about Triplets a year ago exactly. It came up in discussions

with industrial automation professionals regarding simulation

capabilities. I mentioned 6G, 7G, or 8G and Digital Triplets in a

webinar last week to make a point that we need to talk more about the

jobs to be done, instead of the buzzword bingo right now.

The need to adapt to existing ways of

working was also discussed in a webinar [i] for Chalmers University and

The Digital Twin City Centre, about Revenue Models and Business Models.

The importance of understanding the concept, the situation, and the

unique problems that should be solved cannot be emphasized enough,

where existing companies are indeed built to die[ii].

Finding inspiration is not the

challenge. That is just a google away. Finding what problems to solve,

and how to solve them in their unique setting with culture, processes,

people, existing systems, and political agendas can only be discovered

by digging into the reality that exists. It is known that Digital Twins

can accelerate digital transformation efforts. But a lot of the real

use cases are yet to be discovered at scale. But what are the

main parts that Digital Twins are made up of?

"The Digital twin is made up of three

parts: physical entities in the real world, virtual models of those

entities, and the data that connects the two worlds.

- CIO applications

Memoori asks Is the Path to the Digital Twin Future of Buildings Paved By APIs?

https://memoori.com/is-the-path-to-the-digital-twin-future-of-buildings-paved-by-apis/

A digital twin is a digital

representation of a real-world entity or system. In the context of a

building, digital twins express the location and characteristics of

every wall, door, and window, but also every pipe, cable, and switch in

a virtual model. In our increasingly smart buildings, digital twins

must also mirror every system, device, and connection to truly

represent the facility. Buildings are not static entities, however, so

to maintain an accurate digital twin the system must also monitor wear,

tear, and repair, and realize every modification or upgrade, in the

digital model. With many traditional assets and an estimated 1.7

billion connected sensors and endpoints in commercial buildings in

2020, the digital twin has its work cut out.

According to the

tech research firm Gartner, 75% of organizations implementing Internet

of Things (IoT) technologies already use some form of digital twin or

plan to within a year.

Quantum Digital Twins — from system topologies to AI This is part 2 of a 3 part series Troy Harvey, CEO PassiveLogic

The evolution of building and IoT

automation is placing a strain on the demands of installers, engineers,

and manufacturers of equipment. Growing customer requirements, and the

fast moving technology interplays between buildings, occupants, energy,

and the business processes within these structures, are adding to

already overburdened requirements on automation systems.

We as an industry need to come to

grips with the fact that building systems are the world’s most complex

automated systems. Once we do that, we can then address our systemic

problems. Even the smallest buildings easily have thousands of I/O

points — or what we’d call degrees of freedom in robotic analysis. In

large buildings the I/O points can exceed hundreds of thousands, and

with the growth of the IoT industry, the complexity is only growing.

Only once we give buildings their due respect against comparative

cyberphysical systems like autonomous vehicles, Mars rovers, or

industrial robotics, can we start the conversation on what we do to

address the complexity.

In addition to managing this rising

system complexity and evolving customer demand, there is exponential

growth in the diversity of applications and use cases We are exhausting

our tools with workarounds to solve this exploding complexity. We

are asked to model not only the HVAC systems, but the architectural and

engineering workflow. We need more than tags, more that labels, more

than interconnections. We need not only to describe hydronic and air

flows between mechanical equipment, but the data flow within and

between IT and IoT systems. We need to connect not only the building

systems to the structural elements, but also the interconnected

business systems within — whether that is the processes of occupants,

logistics, manufacturing, energy, or any of the myriad services we are

currently being asked to integrate with the building.

If you are starting to Adapt to Twin and Triplet thinking

keep your eyes open for the next big upsetting wave, the Wireless Wave

Washing over new IoT ways to every known enlisted building component

with its descriptions, purpose, address, dynamic location and sharable

data providing rapidly deployable adaptation with automatic network creation and self-discovery.

“The Only Constant is Change” Virtual reality is just not quite the same as the real deal, but in alignment with this month’s publication theme “Adaption”

Phillip Kopp, CEO Conectric Networks

Humans

are very good at adapting and that is likely an underlying reason for

our success as a species so far. But what about our assets? All of the

physical systems we have designed to help us in our quest to survive in

our dynamic Earth home and propagate out into the rest of the Universe.

In particular, those buildings we have developed in order to live in

all types of conditions and climates around the world (and space… in

the not-so-distant future). Arguably one of the oldest and most

important adaptation tools in our inventory. Are our buildings

adaptable to the constant change? What if the environment they were

built to endure changes around them? What if the end-use they were

designed for is no longer relevant? Just for example, all those giant

convention facilities and office buildings that have been empty for

over the last year. These are very important questions for the owners,

operators and users of those very costly assets.

......Let’s

look first into the structural component of how our buildings will need

to adopt to these new paradigms. It is not only possible, but necessary

to rethink how we design and build in the future to make our structures

more adaptable and resilient to changing conditions. However, the

reality is that our entire industry is not well suited to this kind of

sudden, major change either. This begs a kind of reengineering of the

entire industry stack. From how stakeholders like engineers,

architects, technicians, builders and consultants are trained and

deployed, to how buildings are financed and later operated. Building a

structure to meet a specific end use makes it inherently inflexible.

This can be closely tied to local zoning ordinances and master planning

that require certain types of structures to be built in certain areas.

The expected use of an asset over its life facilitates financing its

development. But what if needs change so dramatically that a once a

busy shopping mall dies, and must be repurposed as a corporate office

campus or a multi-family complex? With cities in drastic need to build

resilience to extreme weather and public health or safety crisis, it’s

very likely we will see a rethinking of these zoning systems in the

coming future to facilitate new kinds of multi-purpose buildings. And

with those buildings, a new kind of construction process which

de-emphasizes the importance of any particular stakeholder during early

construction and adds much more value in providing ongoing services to

these adaptable structures, which may be in constant change over their

entire useful life. This is a fundamental shift in the distribution of

resources across an entire industry, including how buildings will be

owned and operated.

In this interview with Don Kasper is VP of Strategy and Business Development at Sentient Buildings, a New York-based software company and master systems integrator.

Sinclair: You mentioned both adaptability and GEB buildings which caught my attention. Can you explain further?

Kasper: Our

vision is to be the data manager in buildings and act as a broker of

sorts to different systems. We can enable simple "If This, Then

That" controls in buildings by connecting all of the various

data-producing systems at the building level but also at the market

level so simple interactivity can be achieved without impacting the

existing controls a building. We've spent a lot of time thinking and

creating our Neuro platform to help future-proof buildings and make

them smarter. Another key feature of Neuro is that it has a simple but

complex user management system that allows us building owners to

provision access to data to any vendor or platform through our API.

This user management system means that a building owner can give access

to a specific device, type of data point, or any system or sub-system

in the building. As an example, sub-meter data can be shared with a

tenant billing company and chilled water data can be shared separately

with an energy services company without having to repeat the data

collection process. This makes buildings highly adaptable since there

is one source of data that can be provisioned at any level to 3rd party

companies. How this applies to GEB is that we can broker data between a

demand response company and allow them to increase thermostats by 2

degrees through fleet management in anticipation of a demand response

event.

In 2016 this was the first I heard of twin thinking and first met Kasper Software Platform for Automated Analysis & Man vs Machine (Learning)

This article suggests we give every asset an IP address Low-cost Asset Tracking Asset

tracking by providing a simple, low-cost SaaS service that allows

clients to locate their assets when they are needed through a simple

search interface. Jim Henry, Spotto - Investor / Business Development Manager

Real-Time Indoor Asset Tracking solution company.

Our goal is to make asset tracking

easy, cost effective, targeted and timely so that organisations can

find their assets when they need them. A key advantage of this simple

proposition is that organisations can reduce costs by avoiding

unnecessary duplication of assets, preventing assets being lost (for

instance by being left in the wrong place) and minimising workplace

conflict due to frustrations associated with the ‘disappearance’ of

shared assets.

In 2001 ripples of these waves were starting In this building automation column I wrote;

The

next phase of building automation technology will bring new life to

some traditional equipment. Likewise, it will usher in a rethinking of

what building HVAC systems do, and how they do it. These insights

from our building automation columnist can help you get a running start

on the new wave of controls.

The

next phase of building automation technology will bring new life to

some traditional equipment. Likewise, it will usher in a rethinking of

what building HVAC systems do, and how they do it. These insights

from our building automation columnist can help you get a running start

on the new wave of controls.

Pros Of Controls Componentization

Here are some of the advantages created by the componentization trend:

- Overall lower cost because the controls

necessary for the safety and operation of HVAC subsystems will be

combined with the building-wide control devices.

- Shared

points for safety and operation will be available for building

performance monitoring, eliminating the duplication of these points.

(For example, the chilled-water supply and return temperatures on a

chiller).

- Shared input

information to component control will allow points to be added to the

overall system that would not normally be economical to include.

Example: power usage of a chiller. This information is necessary for

capacity control but could also turn the chiller into its own energy

meter.

- The ability to

add increased functionality for an extremely low cost is inherent in

component control. The custom-designed controller can have the DDC

hardware configuration closely matched to the actual requirements of

the HVAC subsystem.

- Closer

integration of control in the HVAC equipment can occur through sensors

that can be made an integral part of the device by imbedding them in

locations not available to field installations.

- Self-tuning

control algorithms will be more successful because timing and tuning

parameters can be set for the particular device. Time constants and

control characteristics are predictable within the actual device.

Factory performance simulation will provide proof of the actual ability

of the control to self-tune under any conditions.

- The

fact that this same component control will be used on all manufactured

devices will allow the manufacturer the time to closely match correct

control for his equipment.

- Self-diagnostics

will be very sophisticated and an integral part of each manufactured

device. Using appliance-type thinking and assembly line construction,

the component control will be a large part of the quality assurance

effort, providing its own device original and continuous performance

evaluation. The low cost to add the necessary sensing and functionality

to make sophisticated self-diagnostics is achievable and will become

the lowest cost of providing original and ongoing product quality

assurance.

- Increased HVAC product functionality will continue to grow as new control concepts are developed daily.

ControlTalk Now a Video Chat April 4 where we talk about our April issue and digital triplets “As

our mediums of communication evolve, the reach of our voice moves from

local, to national, to global, from workspace to everywhere. We need to

be the change, disconnecting from our learned perceptions — hone our

superpowers.” Adaptation" Ken Sinclair, editor/owner Automated

Buildings.

Good summary here Connected Complexity The Padi Platform:Open-Source Tools For Open Data Represented from https://harborresearch.com/connected-complexity/

We

are at the cusp of a “perfect storm” of smart systems innovations.

Multiple parallel technology developments, including data modeling and

machine learning, are accelerating and enabling more complex and

adaptive systems such as digital twins. Along with the value these

innovations bring, however, grows the complexity of connecting and

integrating machines, equipment and data in a meaningful context. A new

open-source software tool, Connection Profile, enables simple, durable

and context-sensitive integration between complex systems without any

wasteful custom development. It is a great leap forward to the original

vision of the internet as a single, seamlessly integrated cloud.

Digital Triplets? Quadruplets? Componetized Wireless? Adaptation is in your future.

[an error occurred while processing this directive]

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]