|

September 2011

Article

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

|

Roadmap

to Open Programming Language Continued….

This article continues to

develop a

road map to an open control programming language standard by examining

the

difference between IEC 61131-3 standard and the proposed open

instruction set architecture.

|

Nirosha Munasinghe MBusIT

BSc BE (Hons) (Melb)

Product

Development Manager,

Open General Nirosha Munasinghe MBusIT

BSc BE (Hons) (Melb)

Product

Development Manager,

Open General

Contributing Editor

|

Embracing

change in control programming languages created a plethora of

discussions among the who’s who of the BAS industry last month. The

discussions indicated the resistance against change in the BAS

industry and the past attempts to open up the control programming

paradigm by the IEC 61131-3 standard. This article continues to

develop a

road map to an open control programming language standard by examining

the

difference between IEC 61131-3 standard and the proposed open

instruction set architecture. It also outlines the socio cultural

issues behind the open control language in the BAS

industry.

The

articles referenced above:

The Past and

Future of Control Languages

Roadmap for Control Programming Language Evolution Part 1

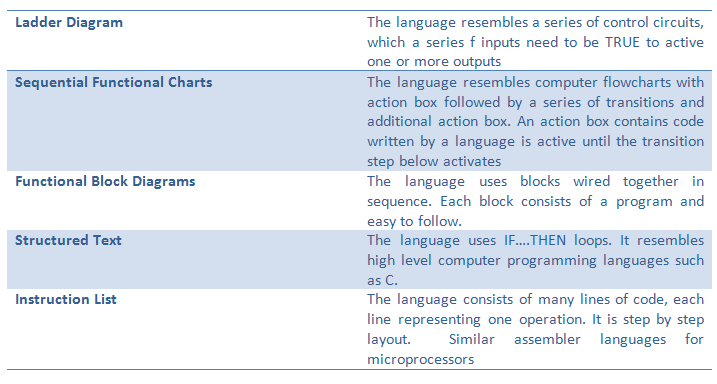

IEC-61131-3

is the first vendor independent standard programming

language for industrial automation. It provides multiple language

support for control programming, allowing the user to select the best

language that is best suited to a particular task or user preference.

The standard is also hardware independent increasing level of software

reusability. IEC-61131-3 as defined suits the following five PLC

programming languages:

The

user selects the language and the hardware supports the

interpretation of the language. Building automation supports similar

languages but the implementation is closed to each vendor. For example

many BAS vendors support structured text languages. Although the syntax

may look similar at a user level, the interpretation of the complied

output is different from vendor to vendor. Therefore the BAS

industry requires a similar standard to IEC-61131-3 to further open up

the industry.

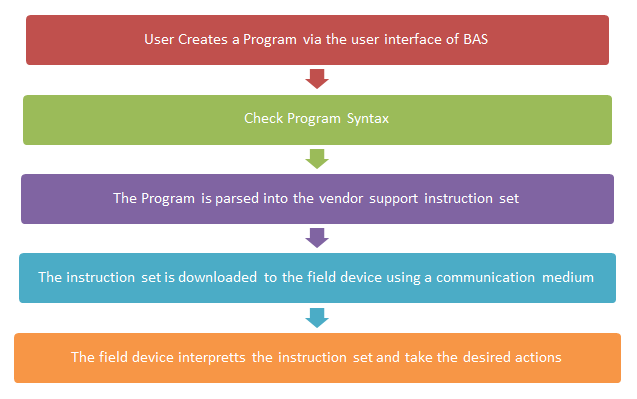

How

different is the “Open Instruction Set” road map suggested in last

month article to IEC-61131-3? The primary difference is that

IEC-61131-3 defines the five different programming languages and its

syntax and taxonomies. The manufacturers user interface must fit to

these languages and its respective rules to comply with the standard.

The open instruction set proposal does not define the programming

language.

It only defines a standard for the output of the programming language,

which is transferred to the devices to interpret. Therefore the BAS

manufacturers can choose any programming language style to match their

customer preference, but once the program is parsed and compiled, it

must be converted to the open instruction set. The following diagram

illustrates the general flow of the BAS program from the time user

programs

using a user interface to final interpretation from the device.

[an error occurred while processing this directive]In open instruction architecture the

program is parsed to open

instruction set and every device which supports the standard, has an

interpreting engine to execute the program.

How do

we implement such architecture? Not a simple task. The BAS

industry is evolving significantly with energy management paradigms and

the requirements to develop complex programs are required. Ten years

ago, a BAS system contained simple programs for fan coil unit, air

handling unit, chiller and boiler. Now, there is a requirement for many

energy saving strategies, which means the standard program from ten

years ago must be re-written to implement the changes. More complex

algorithms need to be implemented via the programming language.

Therefore greater thought and research must be conducted as to what

exactly

is required in a BAS programming language. It needs to be simple as

possible but needs the flexibility to cover the current requirements

and

evolve in the future.

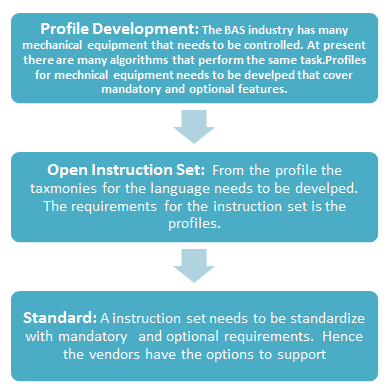

How do

we move forward? An existing BAS manufacturer or a body formed

with representatives from many BAS manufacturers neesd to initiate the

removal of barriers to form the architecture. The following is an

example of a road map the body can follow to develop an open

architecture

for a control programming language.

What

are the barriers? The fundamental barrier is the resistance to

change. Currently, the only method a BAS vendor can lock them self into

a large site is via the programming language. The BAS vendor’s

proprietary software is required to change any program. An open control

language environment will truly open up the BAS industry. Many BAS

vendors prefer the perception of truly being open, while maintaining

some kind of proprietary components to maintain a barrier of entry of

other vendors to the site. In the suggested open instruction set

architecture, the BAS vendor still can maintain a sound competitive

advantage. The architecture does not have a set user interface for the

programming language as long as the output of the language is converted

to the instruction set. Therefore, it will be up to the BAS vendor to

define the actual user interface for the programming language, whether

it will be graphical, structured, text, XML, C, JAVA or multiple

combinations. Every BAS vendor will have a different user

interface. It will be up to the BAS vendor to complete the market

research and develop the user interface to capture the market. The open

instruction set will be hidden on an abstract layer from the user

interface.

Therefore the user interface will be the key feature to winning the

market. The BAS vendor with an easy to use, yet flexible programming

user

interface, can capture the market to gain a competitive

advantage.

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]

Nirosha Munasinghe MBusIT

BSc BE (Hons) (Melb)

Nirosha Munasinghe MBusIT

BSc BE (Hons) (Melb)