December

2009

![]()

AutomatedBuildings.com

[an error occurred while processing this directive]

(Click Message to Learn More)

December

2009 |

[an error occurred while processing this directive] |

|

|

|

Part two of a three part series on the business case for submetering, the measurements required to succeed, and a comparison of available submetering models. By the end you should know the right questions to ask when choosing a submeter supplier.

The Business Case for Submetering - Part 1-3

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[an error occurred while processing this directive] |

Measure where your money is going

When you set

out to get your finances under control you always start with the same thing: you

ask yourself where all the money is going.

When you set

out to get your finances under control you always start with the same thing: you

ask yourself where all the money is going.

If you are trying to control your household finances you save all your receipts

in a jar for a month. If you're charged with reducing company spending you start

with the balance sheet and the cash flow statements.

Managing energy costs is no different. The first step in any good energy

management and cost control program is to get a clear understanding of where the

money is going. It's the only reliable way to find out where your biggest cost

saving opportunities are, and ensure you get a positive return on every energy

management investment you make.

So let's start at the top. In the simplest terms your energy cost spending is

going to your local utility companies. Here's what they are billing you for.

Commercial and industrial utility bills are based on three core things:

How much energy you actually use

The maximum amount of energy you need available on demand

When you use energy

On your utility bill it shows up like this:

Total Energy Use (kWh and kVARh)

Maximum Energy Use in a year (Peak Demand kW)

Time of Use (day, night, evenings, weekdays, weekends)

These are the main things you need to measure and understand.

Other ways energy measurement value adds up

Although the most immediate and measurable costs associated with energy

management programs are on the monthly utility bill, donít be fooled into

thinking that's all there is. Some of the biggest cost savings have nothing to

do with the monthly price of electricity.

Let's look at some other items that are a little harder to measure, but are well

worth some consideration.

1. Property value

Aside from location and building type one of the biggest impacts on commercial

and industrial property value is the building operating costs. Obviously a

building that costs less to operate every month is more valuable to potential

buyers than a similar building that costs more. Lowering your energy costs has a

direct impact on the resale value of your property.

2. Vacancy Rates

More and more property managers are starting to report that tenants are

specifically looking for energy efficient buildings. Public demand has now grown

to the point that it is impacting occupancy rates.

Buildings that are able to share energy usage information with tenants and can

assure people of the fairness of energy cost allocation practices are leasing

faster than buildings without energy management programs. The demand for energy

efficiency is starting to impact which buildings have low vacancy rates and

which ones sit partially empty.

High occupancy rates have obvious benefits to monthly cash flow and over-all

building property value.

3. Preventive Maintenance and Down Time Reduction

Today's energy monitoring equipment can do more than tell you what your total

energy usage is. Advanced per circuit monitoring can warn you immediately

whenever things are out of the ordinary.

Recent advancements in multi-circuit monitoring make it more cost effective than

ever to monitor individual loads. Circuits that suddenly start drawing more

power pinpoint problem areas. High current draws often mean struggling equipment

pointing to areas that need assessment. Increased power to a compressor can mean

failing bearings or leaky compressor hoses. Low power factors often indicate

problems with motors and generators.

You may not need all the full level of detail in the beginning, but it is

important to build a monitoring system that can expand to meet your needs as you

move forward and become more knowledgeable in energy management.

4. Reducing Wasted Energy

It is surprising how much energy is wasted simple because people donít turn

things off when they are not in use. Energy management programs save a lot of

money by identifying high usage areas that remain high power users even after

personnel have gone home.

Having measurements of where and how often lights and other equipment are being

left on can help you assess whether or not the cost of lighting automation

systems or on/off timers is worth the investment. Just being able to show people

how much money it costs to leave things on unnecessarily is often enough to

prompt them to flick the switch when they leave. If that doesn't work an

automated email or text message to the facility manager can tell him when he

needs to walk over and turn something off himself.

In addition to units of energy usage you should also be measuring, or at least

considering the impact on property value, vacancy rates, preventive maintenance

and wasted energy.

What should you measure?

Utilities charge you for three things: total usage, peak demand, and time of

use. There is more than one way to save money using submetering. So what exactly

should you measure with a submetering program? The answer depends on what you

want to do.

There are three basic reasons for implementing a submetering program:

Utility bill auditing and allocation to tenants

Energy management to drive cost reduction through lower energy usage

Power quality assurance for critical equipment

The type of system you need depends on which of these

three things you are trying to accomplish.

The objective of bill allocation is to fairly and accurately charge each tenant

or department on the premises for their portion of the total energy bill. This

type of metering also allows you to audit the utility bill by having submeter

readings you can check your bill against. This protects you against billing

errors due to failing or broken utility meters.

The objective of energy management is to reduce your overall energy bill by

reducing the total amount of energy you use. More and more we are seeing that

this is where the real money is.

The objective of critical equipment assurance is to make sure that the power

being provided to critical equipment is of the quality and consistency required

to ensure the equipment runs optimally and never fails.

So let's take a look at the type of measurements you need to address these three

different submetering objectives.

Utility

Bill Cost Allocation Measurements

Utility

Bill Cost Allocation Measurements

Cost allocation programs are most commonly used in multi-tenant commercial

and residential buildings to split up the bill fairly between tenants.

If this is your objective, there are some key measurements your electric

submeter needs to provide:

kiloWatt Hours (kWhr)

This is the basic unit of billable electric energy. Many residential

buildings use kWhr metering and nothing else to allocate the bill.

Peak Demand (kW)

Peak demand meters keep track of the most amount of power you ever used in a

short duration (usually 15-minutes). In very small buildings the utility may

not bill you for peak demand.

Time of Use (TOU) - optional

If your utility bill has multiple billing rates for different times of the

day or week, then your submetering system should also be able to break

things down in the same way. Meters that do this are called TOU meters.

Revenue Certified

Submeters used explicitly for the purpose of generating a bill for each

tenant must be revenue certified in North America. This type of meter tends

to be more expensive than similar non-revenue certified meters.

The simple act of making each tenant responsible for

their portion of the bill can lower overall energy usage significantly.

While this is good news for building owners, tenants (IE voters) and legislators

(who generally side with voters) are starting to demand these cost savings be

shared with them. While cost allocation systems are still valuable this trend is

starting to reduce the value of simple cost allocation metering systems.

Facility managers are starting to see that from a cost-saving perspective this

type of metering is only the tip of the iceberg.

Energy Management Measurements

In an energy management system the focus is on reducing the amount of energy

being used, which in turn lowers your overall energy costs.

A good energy management system needs these measurements:

kW hr

this is the total amount of electrical energy you are actually using and

paying for.

kVAR hr

Without getting too technical, this is unusable power that you still have to

pay for.

If your kVAR readings are consistently high there are system adjustments, and equipment your local electrical contractor can install to minimize this. The only way to know whether or not this equipment is justified is to know the cost associated with not doing it. kVAR hr measurements are how you calculate costs associated with this type of wasted power.

kVAR hr readings are particularly important wherever you have spinning motors or generators. Common examples include machine shops, laundry facilities, cooling or refrigeration units, and forced air heating pumps.

Load

Profile / Interval Data

Load

Profile / Interval Data

If you plan to go beyond billing allocation to really drive energy cost

savings interval data is a must.

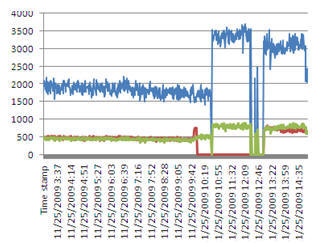

1 minute, 5 minute or 15 minute interval data is probably the most powerful

cost savings enabler available to you. This is the data that paints the real

picture by graphing out your actual energy usage. In addition you can get

profile data for kW, kVAR, V, I, harmonics and a lot of other things. Each

piece adds additional detail to the picture.

With load profile data you can see what is causing your peak demand load.

You can see what is left running all night. You can see if something changed

from last week. You can see if your new equipment is really any more

efficient than the old stuff. You can recreate time of use data even if your

provider changes the billing structure (something TOU meters would need to

be reconfigured to do). Anyone who is interested can get a lot of

information from this and when issues arise the data can be given to energy

management experts for further analysis.

Reporting system

Your energy management system must have a reporting system in place that

provides you with the information you need to manage your energy costs. We

will get more into this in the third and final part of this series.

Alarming system

When unusual events happen, you can save a lot of money if you find out

about them right away. Equipment problems that are only discovered after

digging in to see why the last bill was so high have already cost you more

than necessary. Good energy management systems can email you right away when

unusual things happen so immediate corrective action can be taken. We will

discuss this more in the next part of this series.

[an error occurred while processing this directive]

Power Quality Monitoring

Power quality monitoring is used primarily in data centers and industrial

sites with critical equipment. This is a specialized area of its own so we will

only touch on it briefly for the sake of completeness.

Not all power generation sources provide the same quality of power. For normal

residential and commercial use most available sources are fine, but when you get

into managing critical loads the quality of your power delivery becomes very

important.

Power quality meters commonly provide the following information

Size and duration of any voltage sags, swells or interruptions

Voltage unbalance & load unbalance in multi-phase systems

Frequency monitoring

Harmonic distortion

Digital waveform recording down to the millisecond

Summary

Before you start any energy management program you need to set your

objectives clearly.

Do you want to allocate the utility bill to your tenants?

Do you want an energy management program that will identify cost savings opportunities and help you reduce energy usage?

Do you need to monitor power quality to ensure proper operation of sensitive or critical equipment?

Once you have set your objective make sure the system

you install provides you with the appropriate measurements.

In the upcoming final part of the series we will discuss the pros and cons of

various different types of systems and business models used in the submetering

industry.

About the Author:

Daryl Cowie is business development manager at Wescon Technologies. For more

information on how to justify and choose a system that fits your needs visit

http://MultiCircuitMetering.com to

get 2 free reports:" Show Me the Money - real life submetering cost savings

examples" and "The Facilities Manager's Submetering System Checklist - basic

requirements, options & standards"

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The Automator] [About] [Subscribe ] [Contact Us]