|

December 2018

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

When

you read through this whole series of articles you may ask:

- Why are you telling me what’s inside a controller? Should I care?

- Can’t I just buy a controller and use it? Are you telling me I

should

make one for myself?

Not

necessarily. Although if you wanted to make your own controller, you

could. The reality is, none of these devices contain any parts that are

truly proprietary or unavailable to the public. At least not anymore.

Most modern DDC controllers are composed of parts that are off-the-shelf

items. Many of the various bits and pieces of these devices can

be found in singles from large online retailers such as Digikey or Mouser. Components,

boards, sub-assemblies, and starter kits can be found on hobbyist sites

such as Adafruit

and Sparkfun.

Sample and low-volume prototype printed circuit boards can be

inexpensively fabricated from places like OSH Park or Macrofab. It turns

out that it’s completely possible to build your own edge controllers.

Not only that, but it’s also possible to buy just enough pieces to make

just one controller; if you

are so inclined.

This

is kind of a big deal. In the past, someone with a passing interest in

electronics could not very easily experiment with these types of

devices. They would have to commit to buying thousands of units as

opposed to purchasing just one chip. Access to datasheets and reference

manuals needed for evaluation and design required extensive legal

agreements and signing of non-disclosure forms. Software and tools to

compile, flash, and test various processors were often extremely

proprietary, difficult to use, and prohibitively expensive (like

thousands of dollars). These pricey development tools were of course

not cross-compatible with other vendor’s chips. It was not very easy to

test out and learn about products from different manufacturers.

All

of these concerns have largely disappeared in the past decade. Many of

the barriers to entry have been removed by several of these parts

vendors. They have done this to make it easier for someone with a great

idea to be able to evaluate and choose their chip to use in a new

product. To make it even easier, most companies offer low-cost development boards for accessing a particular

chip’s features much faster. The wide availability of these open

components and supporting tools has enabled the growth of a movement in

the electronics world. This is sometimes referred to the Maker Movement.

However,

this series is not meant to be a how-to on building electronics for

control. There are plenty of such resources already in books or online.

The purpose of these articles is more of an architectural tour. The

control devices that we will inevitably be installing in our buildings

will be by necessity open-source, open-architecture, and extensible. It

will become important to become familiar with the overall layout of

these new systems so that the controls industry can be streamlined when

entering this new era. Someone doesn’t have to be a professional

hardware or software developer to be able to appreciate electronics and

software. Just like someone can study building architecture without

being involved in the construction industry. With the introduction of

newer, powerful, and cost-effective embedded microprocessors, much of

the tasks usually performed by global controllers, gateways, or BMS

servers will be pushed out to the edge; to the field devices actually

controlling and monitoring equipment. What’s needed is an understanding

of what edge controllers can do and should be required to do. By

studying edge controller architecture, one can develop an understanding

of what should go where.

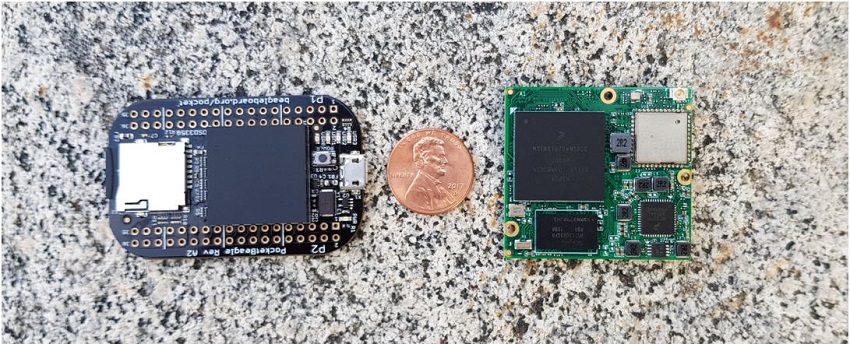

These are completely self-contained

personal computers

The

Processor

Until now the question of what data and processing activity should go

where was easy to answer. Field devices have to be low-cost products.

In the past, it was only cost-effective for field controllers to be

constructed using microcontrollers as the central component. These

simple devices are limited in processing and storage capability.

Because a microcontroller can do only a few things at once, that meant

it would only run the DDC program for the equipment it’s attached to,

and usually nothing else. Just a little bit of processing and data went

into the controller; in many cases not even occupancy schedules or

historical trends. All of that stuff normally went into a global

controller or gateway/router. The schedules and histories would more

easily be hosted there. But the vast majority of everything else went

into the server, which is usually a desktop PC sitting on a folding

table in the boiler room. In the era of edge control, everything has

changed. That desktop PC now exists on a single piece of silicon, and

its location is in the controller for every single zone.

[an error occurred while processing this directive]

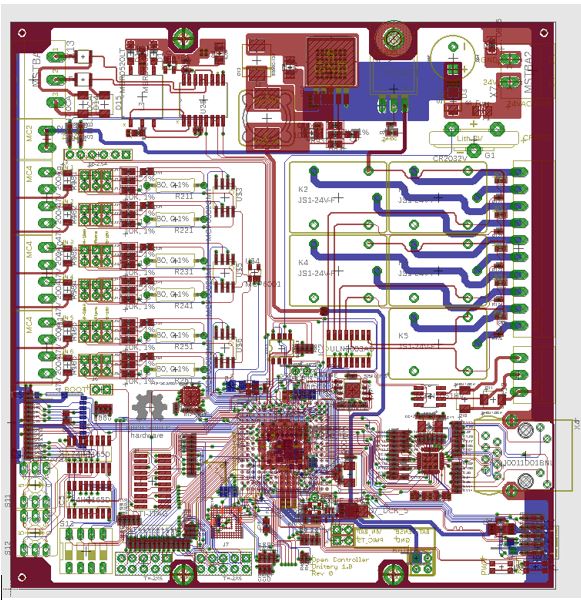

The Hardware

Board peripherals and controller form factor continues to be an

important consideration. At the end of the day, having a complete

personal computer on a chip is totally useless unless it’s connected to

interact with the actual equipment we care about. Increasingly new

controller products are being equipped with IP connectivity. Will we

continue to see controllers daisy-chained together using serial ports?

BMS network topology is destined for an inevitable overhaul. Will

features such as PoE and Wireless help alleviate some concerns about

installation costs? The most important issue for controls contractors

is the installation workflow and device commissioning. How will we

tackle the task of assigning IP addresses and commissioning hundreds of

devices as opposed to doing just a few? Some things will probably

remain constant, however. The way I/O is done will probably remain the

same, but improvements can be made by standardizing how these points

are brought into the system. For example, creating a uniform and

streamlined way for I/O read-writes through OS kernel system calls. The

underlying infrastructure in embedded Linux already exists to support

this.

The Software

Finally, a discussion on platform software/firmware and User

Applications. The reason for all of this focus on hardware is to

guarantee support for all of the applications that will run on these

devices, both at present, and in the future. Solid hardware is the

foundation that future BMS applications will be built upon. One of the

main reasons to transition from single-threaded devices using

microcontrollers to multi-threaded operating systems is to future-proof

these devices (at least as much as possible). Future controllers will

still need to run DDC programs reliably and in real-time.

In addition

to doing what they always have done, these products will have to manage

other processes without failing in their main purpose. They will have

to do this in a secure manner and be capable of being upgraded/updated.

So, if you are interested in what goes inside an edge controller, stay

tuned as we will explore each of these three topics in depth, starting

next month with The Processor.

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]