AutomatedBuildings.com

Article - January 2002

[Home Page] |

[an error occurred while processing this directive]

(Click Message to Learn More) |

|

|

The application of a standardized and

internationally accepted protocol for specific applications is still no

guarantee that a device by manufacturer A can be exchanged for one supplied by

manufacturer B. For this purpose, further standardization of design and of the

exact functionality of a device is necessary.

|

Hans R. Kranz

& Othmar Gisler

Siemens Building

Technologies Ltd

Building Automation, Zug, Switzerland

|

ABSTRACT

A short overview on today's trends in BACS

(Building Automation and Control Systems) is presented. The influence of

standard protocols and web technology is analysed, and some of the most

promising ones, in the author's view, are analysed in more detail. The actual

status of the different standard protocols by international standard bodies is

outlined. Finally an outlook is given to how the future in the building

automation world could look in the next few years.

TABLE OF CONTENTS

Trends

and Future Challenges in Building Automation and Control Systems

The Technology Behind

The What, Why and Where of

Standards

What

Has to be Covered by Open Communication Standards for Building Automation and

Control Systems?

BACnet versus LonMark

European Standardization

International Standardization

BACnet, EIB/KNX,

LonMark, etc. - Where to Use What

OPC - A New Alternative?

Some Actual

Customer Needs Covered by Web-Technology

Embedded Web-Server

versus Application Server

Application Server - Target

Groups

Application Server - Solutions

General System Architecture

Will Web-Technology Replace

BACnet?

Summary and Conclusions

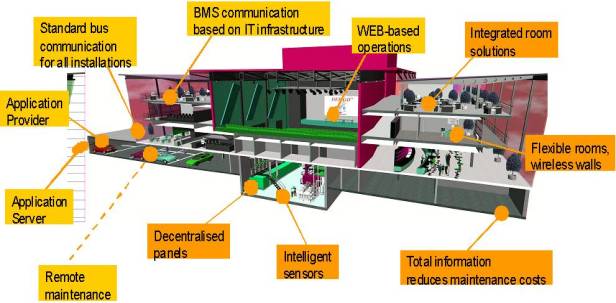

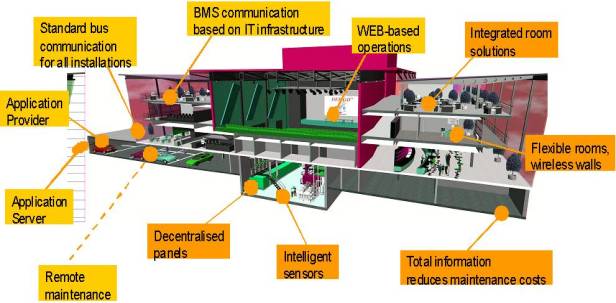

TRENDS

AND FUTURE CHALLENGES IN BUILDING AUTOMATION AND CONTROL SYSTEMS

Facilities must meet business needs more and more

closely and reduce operating and maintenance costs. Leaner budgets and

environmental considerations demand advanced energy management. Growing

expectations for comfort and service require advanced managerial instruments.

Every enterprise has a unique pattern of building

management requirements. Freedom to choose the right solution to meet specific

needs is crucial.

It's time to change the way we look at facility

and building management. Only a coherent automation and control framework,

within which many different systems are to evolve, can remove the barriers to

progress. A common interface, Open, normative system standards, Web Technology

and advanced integration are prerequisites for success.

Below is a list of actual customer requirements.

-

Reduction of initial investments

-

Building Automation uses existing IT and CT

infrastructure

-

A unique user interface for all building

disciplines (HVAC, Lighting, Lifts, Fire, Access, Intrusion,

)

-

Customers want higher supplier independence in

case of later system enhancement

-

Reduction of operating, energy

and

maintenance costs

-

Mobile operators want to operate the building

at any time, from everywhere, immediately

-

Less trained operator needs

"obvious" operating

-

Technical competence centre serves many

buildings in a defined geographical region

-

Growing expectations for comfort and service

-

Reduced energy consumption

the answer: System and

Communication Standards and Web-Technology

THE

TECHNOLOGY BEHIND

[an error occurred while processing this directive]System

Standards for BACS

The main expenditure is in the efforts for the complete engineering of BACS

plants. The costs are in direct relation to the type and amount of functions

necessary. The I/O points just provide - or use - the signals. To avoid

unnecessary risks for costs at tendering, execution and billing the use of

standardized terms is necessary. Free and fair competition, including the potential

for innovations, is only possible by specifications using a unique language for

all parties involved. The CEN/TC247WG3 has developed a set of standards for a

common understanding of hardware and functions. This definition of functions

helps i.e. in the case of system integration to determine the tasks of each

involved system and to calculate the proper costs for the system engineering.

This work has been adopted by the relevant ISO committee TC205.

Communication Standards for BACS

Standardised communication protocols such as BACnetTM, EIB/KNX, LONMARK®, etc.

and interfacing standards such as OPC (OLE for Process Control) allow exchange

of information between different manufactures devices, systems and programs in

an agreed way. Communication standards are the prerequisite for cost efficient

integration of various manufactures subsystems.

IT & Web Technology

State-of-the-Art

IT and Web-Technology is widely used by BACS. This allows smooth

data-exchange with the customer's office automation system and business process.

Existing communication infrastructure such as LAN / WAN (Wide Area Networks) can

be shared - which reduces cabling cost and allows flexible solutions. Web

technology brings additional benefits such as easier and central software

updates & maintenance / local operation using slim, low cost clients (only a

browser is needed).

Some of the most important

technologies from the IT world are: Ethernet, TCP/IP, Int@net, Web, OLE/COM, XML,

SOAP.

Communication standards for

BACS IT & Web technology

THE

WHAT, WHY AND WHERE OF STANDARDS

Efficiency Means Profitability

An integrated management system enables a building to be operated more easily

and with greater efficiency, so helping to reduce operating costs and increase

profitability. Instead of using a variety of dedicated devices for operation,

the facility manager's team can perform all activities from operator stations

with the same look and feel, keeping training and operating costs to a minimum

and reducing the likelihood of incorrect operations. Dedicated security systems,

of course, send their alarms to the security guards and the

fire brigade. However, if information of all systems in the building is brought

together to one or to many networked operator stations with unique human

interface, faults and alarms can be identified and dealt with immediately, for

the better protection of people and property.

Precondition for System Integration

Stable and reliable communication is one precondition for system integration. Protocols

and functions must be exactly described if successful performance and

integration is to take place. In the case of multi vendor systems integration, the

right contracts, mutual coordination and agreed upon responsibility is

indispensable. Nevertheless, there are practical limits to implementation:

-

The fusion of different concepts is difficult

and demands considerable investment of time and energy. This is hardly

justifiable for a single application!

-

The delimitation of responsibility at the

interfaces and uncoordinated alterations in the subsystems represent almost

intolerable complications for integration.

To overcome these limits the industry agreed on

communication standards, which describe the basic functions in the disciplines

of HVAC, lighting, safety, etc. These basic functions defined as objects can

then be exchanged by different services, disciplines or management systems

easily and with a minimum of effort via communication networks, routers,

gateways etc.

Integration will only be really successful,

however, when standard protocols are implemented internally within the

individual systems. This eliminates complex conversion and, above all, too much

loss of functionality. The standardization of engineering data and the

engineering and commissioning workflow in the future will further help to lower

costs and to increase the reliability and functionality of integrated

systems!

Typical applications in a building: air, water,

lighting and sun-blinds, heating, cooling, ventilation, energy distribution,

safety and security, refrigeration, transportation and ancillary systems.

(The user; source: Michael

Newman, ASHRAE)

Integration plays a key role in bringing down

operating costs and allows us to look at the building as one single process.

WHAT

HAS TO BE COVERED BY OPEN COMMUNICATION STANDARDS FOR BUILDING AUTOMATION AND

CONTROL SYSTEMS?

I would like to highlight some concepts on which

to focus our attention when deciding which protocol is the right solution for

BACS.

The involved parties should consider different

topics when deciding which standard protocol fulfils the requirement. The

following main issues have to be addressed:

|

|

has to

provide all complex and simple data structures to accomplish daily

functions like:

|

|

|

-

Exchange

data between devices

-

Monitor

& operate inputs, outputs, setpoints, alarms

-

Time

Scheduling

-

Online

Grouping / Regrouping

-

Trend /

History

-

Backup /

Restore

|

|

|

The

data approach has to be object oriented.

|

|

|

has to

support services for system start-up, network management and

back-up / restore.

|

|

|

has to

provide independent media access to support modern IT & CT networking

standards and cabling systems.

|

|

|

has to

allow extensions to provide the possibilities of future innovations.

|

The European standardization committee had to

weigh up over 100 issues for the selection of the present pre-standard

protocols.

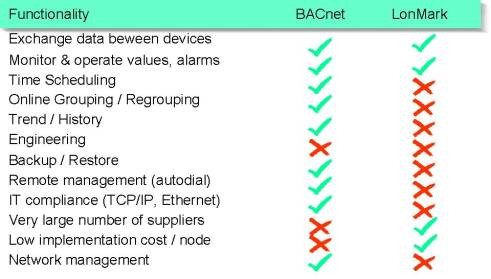

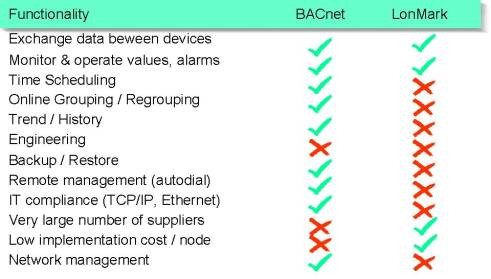

BACnet VERSUS

LONMARK

If we apply above criteria to BACnetTM and

LonMark® we get the following picture.

. and as we can see, a clear positioning where

to use what:

LonMark®

[an error occurred while processing this directive]

We talk about

LonMark, because the LonTalk® protocol is a proprietary product from Echelon

Inc. The defined LonMark

templates cover the functionality needed for the field level: Data

exchange and interactions between devices on the same bus, monitoring of values

such as temperatures, operating states and simple control functions e.g. lights

on/off, etc. The field device functions are normally implemented in one single

chip (the Neuron® and the LonWorks® transceivers support a range of

transmission media, e.g. the inexpensive Cat. 4 cables. In addition there is a

relatively large (>180) number of manufacturers available to choose devices

for building applications from, but the product's ability for interoperation has

to be checked by the system integrator.

All this may give the LonWorks based

products a future potential to network at the field level. But

"normal" sensors and actuators cost less - from a point of view

without taking the overall system costs and the engineering into account.

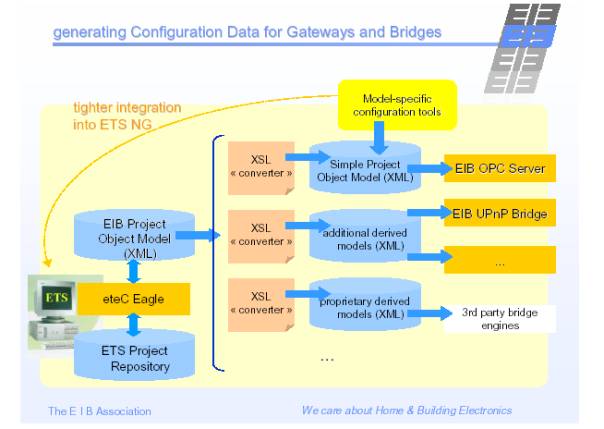

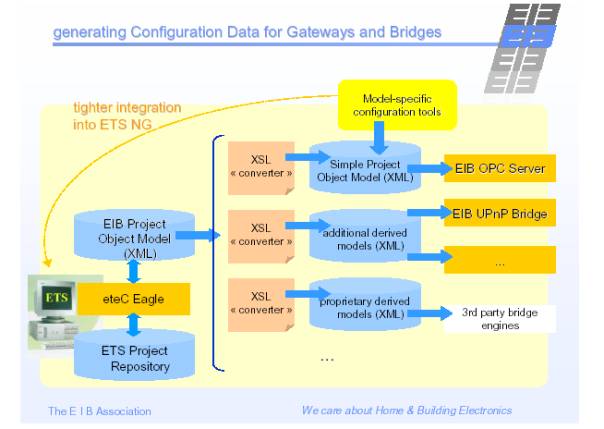

EIB/KONNEX

The application of a standardized and

internationally accepted protocol for specific applications is still no

guarantee that a device by manufacturer A can be exchanged for one supplied by

manufacturer B. For this purpose, further standardization of design and of the

exact functionality of a device is necessary. One step in this direction has

been made by the EIB concept for building applications. Each of the more than

5,000 available EIB devices is supplied with its relevant parameterization data

stored on a floppy disc which can be used - together with the neutral EIBA tool

software ETS (11.000 licenses in use) - by the installer for combination. (EIBA

= European Installation Bus Association, Brussels/Belgium).

There are 65

certified training organizations and 15 national EIBA Organizations. More than

70.000 projects have been finished all over the world.

Today's market provides

such an extreme diversity of applications that an all-comprehensive testing

procedure is hardly feasible under economic aspects. Testing is less arduous and

expensive for less sophisticated devices (e.g. devices for the European

Installation Bus EIB) whose range of functions has been defined through "interworking

standards". The EIB Functional blocks describe not only the semantics of a

function in English language, but also define how to access the services

associated with that function. This is done on the base of Data Points.

The EIB

Communications Protocol is part of ANSI EIA 776.1 to .5 standard and

incorporates a CEBus - EIB Router.

EIBA has been assigned a unique BACnet vendor

ID (74, decimal) by the ASHRAE organization. This vendor ID must be used for the

mappings of EIB applications to BACnet. The document ISO/TC205WG3 BACnet draft

addendum H.5 describes how European Installation Bus (EIB) Functional Blocks,

which are part of Object Interface Specifications (ObIS) of the Interworking

Model defined by the EIB Association (EIBA), are mapped to the corresponding

Building Automation and Control networks (BACnet) object model definitions.

EIB - the true interchangeability

In a convergence project the three European

Associations EIBA, BCI, EHSA have been migrated to the Konnex Association (March

2001) and the protocols "EIB", "BatiBus" and "EHS"

grow together to the "KNX" (Konnex) protocol.

BACnet

In most other protocols there are some

basic BACS functionalities missing for open interoperability. Services and

functions which are needed

for mature building management such as: Trend / History, Time Scheduling,

Back-up/ Restore, Remote Management, Alarm Distribution, and many others.

BACnet covers all these requirements. In addition

BACnet supports, in a flexible way, modern IT and networking technology such as

Ethernet and IP (Internet Protocol) as this is needed in today's modern IT

environments.

BACnet is therefore the best choice for the upper

system levels where a broader functionality and full IT compliance is needed.

EUROPEAN

STANDARDIZATION

After having analysed these main topics in order

to decide which standard protocols are preferred for our BACS system, we should

have a look also at the standardization situation in Europe, because there,

the open communication was started earlier then anywhere else. Implementation

began in Germany in 1984 with IBM's FACN protocol, followed by the

FND in 1987.

European pre-standards for communication

protocols in BACS:

As we can see there is not just one single

communication standard - but for each functional "system level" there

is a choice of various standards with different functionalities and benefits.

Since there were over 20 protocols in the beginning of the standardization

process (1990), the decision was to limit the number to three per functional

level. So the consensus, rather than the compromise, is shown in the picture.

Fortunately the experimental standards may only stay for 5 years, then a new

decision must be made. The FND was withdrawn as a standard in 2001, but it

still is there as a "private" public document. The experts within CEN

decided to treat the other protocols also in relation to their acceptance in the

marketplace.

BACnet is the only standard covering management,

automation and field level functions in an open standardized way, supporting

various data transportation methods. This brings additional benefits for

customers and system integrators: Since no protocol conversion is needed we get

higher functionality at lower cost (no gateways needed) - the upper two system

levels can be collapsed and even more complex field devices can be integrated.

On the field level both EIB/KNX and

LonMark have

future potential. EIB, BATIbus and EHS are about to evolve to one new standard:

KONNEX (KNX), the EIBA has migrated to the Konnex Association covering over one

hundred producers.

-

LonMark is well suited for complex field level

applications where a certain engineerable flexibility is required.

-

KONNEX (KNX)

will be optimal for standard solutions - cost effective, simple and easy to

implement.

INTERNATIONAL

STANDARDIZATION

The ISO/TC205 committee treats the

Building Automation and Control System in its WG3 standard. This covers hardware,

functions, applications, communication, conformance testing, project and system

implementation. There is only one protocol without any level dedication: BACnet

as ANSI/ASHRAE 135. It is expected that the EIB/KONNEX Functional Blocks, which

are part of the EIB Object Interface Specification, will become a part of the BACnet

specification by mapping them to the BACnet objects. It is also expected to have

the first worldwide enquiry in 2002. This ISO enquiry will be also be done in

parallel among European countries, so we can expect to have one protocol

standard for BACS all over.

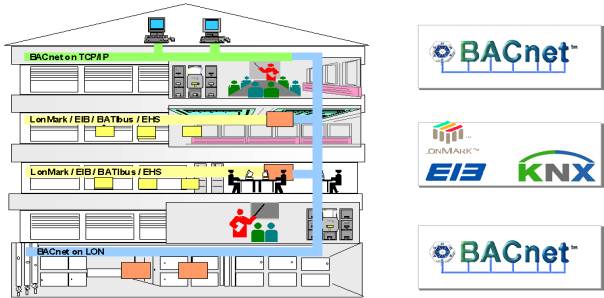

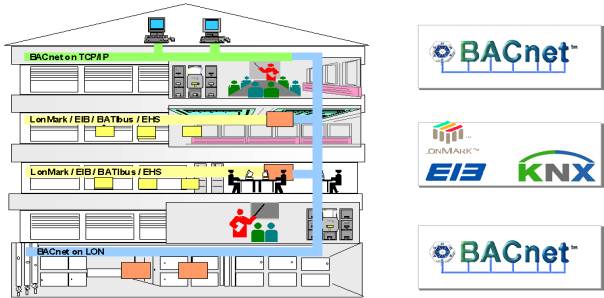

BACnet,

EIB/KNX, LONMARK, ETC. - WHERE TO USE WHAT

So where to use what? After considering all the

above the picture gets clearer.

On the floors, for Room Automation, where a large

number of devices have to be linked together and to interact - EIB/KNX for real

open craftsmen solutions and - LonMark for more complex engineered solutions.

Both offer good cost-effective products covering the functionality needed.

In the plant rooms - more functionality is needed

- this functionality is currently best covered in a standard way by BACnet. For

BACnet the most effective physical media has to be selected, e.g. the same as

for the floors. For management applications we need in addition to BACnet's high

functionality also its IT compliance, so here BACnet on Ethernet/IP will cover

the requirements.

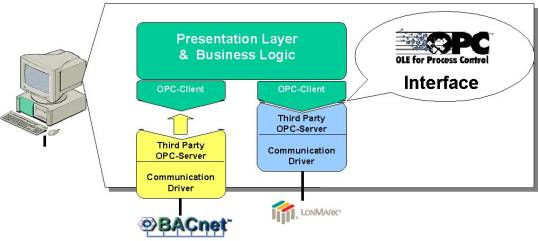

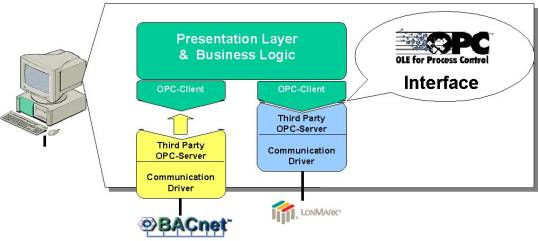

OPC - A NEW

ALTERNATIVE?

OPC stands for "OLE for Process

Control", a communication standard based on OLE/COM technology that brings

the same benefits to industrial hardware and software that standard printer

drivers brought to word processing.

Based on Microsoft's OLE, COM (Component Object

Model) and DCOM (Distributed Object Model) technologies, OPC consists of

standard interfaces, properties and methods for use in process control and

manufacturing-automation applications.

The OLE/COM technologies define how individual

standard components can interact and share data.

OPC provides an interfacing standard for factory

automation where every system and every communication driver can freely connect

and communicate. Having such a standard, the communication and

interactions between different applications, from the plant to the MIS

(Management Information System), becomes easier with truly open enterprise

communication.

OPC

what it is not?

OPC is not a new

standard bus or a universal protocol, but it is an interface definition defined

by different companies from industrial automation and Microsoft.

The complex data structures definition are not

yet fully defined in OPC, leaving them dependent on the application. From the

driver point of view, it is still vendor specific.

SOME

ACTUAL CUSTOMER NEEDS COVERED BY WEB-TECHNOLOGY

Web technology is found almost

everywhere. The following attributes go with the Internet, which are also valid

for web applications within BACS:

-

Global connectivity

-

Global companies need

global BMS information

-

Easy to operate

-

Access at any time, from everywhere,

immediately

-

Use mainstream technology

-

IT-world compliance

-

Slim,

inexpensive clients

In addition, the web technology facilitates and

centralises software maintenance, updates and support. Last but not least, the

web offers new services and opens up new business opportunities.

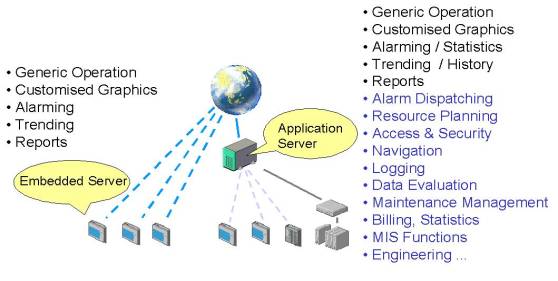

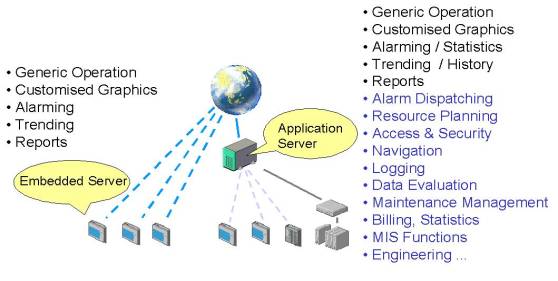

EMBEDDED

WEB-SERVER VERSUS APPLICATION SERVER

Web technology can be implemented in

almost any

device from small embedded systems like a DDC controller to large application

servers. Do we need in future still conventional management stations or can they

be fully replaced by embedded systems?

Let's look where BACS functionality

can be realised using web technology:

As we can see, for small and simple applications

where functionality such as graphical plant operation, alarming, simple trending

and reports are needed embedded Web-Servers can and will fully cover this area.

For larger and/or distributed installations where centralised functions such as

navigation between various sites, alarm dispatching, data evaluation, billing,

statistics, maintenance management, etc. are required a central application

server will be needed.

Web-embedded systems and application servers are

complementary. Functionality and data management is distributed on autonomous

servers within an intranet / internet.

APPLICATION

SERVER - TARGET GROUPS

Application servers will address the following

target groups:

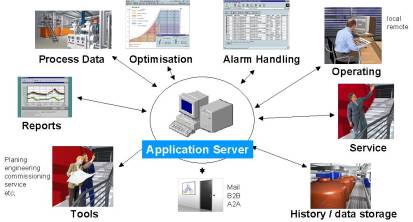

APPLICATION

SERVER - SOLUTIONS

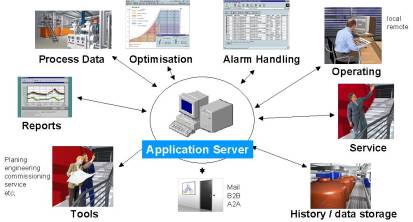

The application server will primarily support the

following technical and technological solutions:

Operating

-

Reporting

-

Alarm handling

-

Plant

optimisation

-

Security

-

Lighting

-

HVAC

-

Media access

-

Room Automation

Data Management

-

Reporting

-

Energy data

evaluation

-

Consumption Control

-

Process data evaluation

-

Trends

-

Billing

-

Error and System Log

Service and Maintenance

Integration Platform

-

Integration on operating

level (e.g. using ActiveX)

-

Subsystem integration via standards communication

protocols and interfaces (BACnet, EIB/KNX, LONMARK, OPC, ... )

-

Data exchange

with customers business processes, office environment, etc.

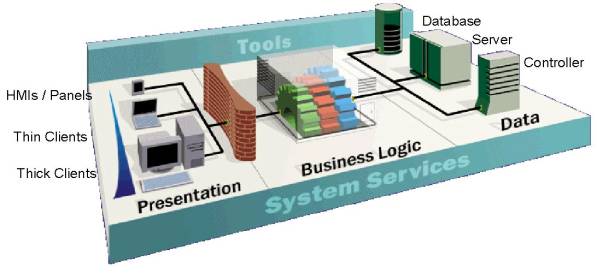

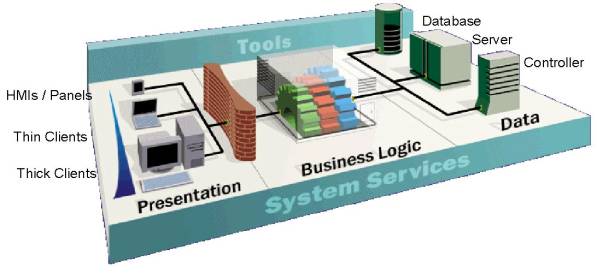

GENERAL

SYSTEM ARCHITECTURE

In the traditional Windows based management

stations business logic and presentation (using e.g. MS Windows) are running on

the same HW platform, normally a personal computer. With state-of-the-art web

technology the presentation layer and the business logic is separated.

To view

and operate the system only a simple web browser is needed, which runs on a

large variety of clients. The core part, the business logic, where functions

such as alarm routing, trend / history data evaluation, etc. are realised,

remains on a dedicated machine, the application server.

Real-time process data

is handled by dedicated DDC controllers optimised for the various building

management disciplines.

Standard database, preferably the leading IT standards

SQL / MSDE are used to store engineering and process data on the management

level.

WILL

WEB-TECHNOLOGY REPLACE BACnet?

Communication protocol between web-server and

clients is based on the leading edge Internet technology such as HTML, DHTML,

XML, SOAP, .NET-framework. These standards out of the IT world are optimised for

their specific purposes: to transmit data needed for presentation by slim to fat

clients through firewalls over the Intranet / Internet.

For communication between subsystems and

application server the specific BACS functionality such as trending / history,

alarming, scheduling etc. has to be covered. Here BACnet is the right

choice. Only BACnet currently provides this functionality within an open

standard format - to assure interoperability between different systems in an

open way.

So we see both BACnet & the Web are needed!

SUMMARY AND

CONCLUSIONS

-

Proprietary communication protocol will lose

importance.

-

There will be a limited number of communication and interfacing

standards which will dominate.

-

BACnet, EIB/KNX, LONMARK, OPC have good future

potential.

-

Debundling - best of breed solution for every level / application.

-

More and more integration of all technical applications.

-

Turnkey solutions from

one supplier.

-

Web technology will be used on operating level.

-

Both embedded

servers and applications servers will play important roles and allow distributed

functionality and data management in geographical networks.

-

Technologies with

very good future potential are: HTML, DHTML, XML, SOAP, NET-framework.

-

BACnet,

OPC and Web are complementary technologies.

-

Application Service Providers will

offer new ways to operate optimise and manage a building.

And do not forget: We have tried to explain in

which direction the building automation and control industry is moving - as

usual, however the marketplace will take the final decision!

More

Articles

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]