|

March 2015

Article

AutomatedBuildings.com

|

[an error occurred while processing this directive]

(Click

Message to Learn More)

|

|

From Buildings to Campuses to Cities

and Beyond…

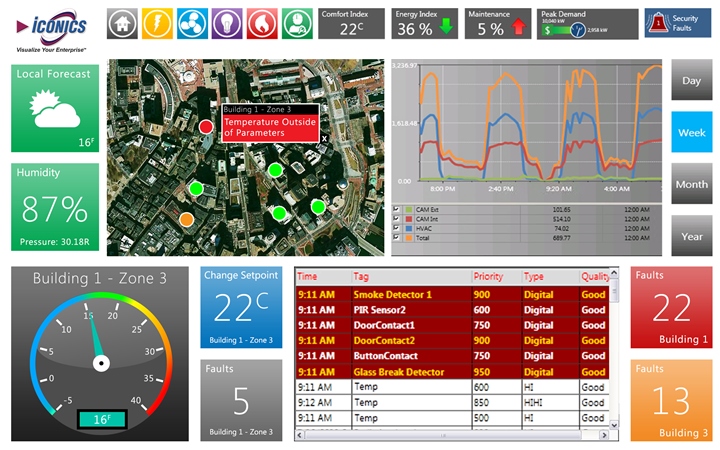

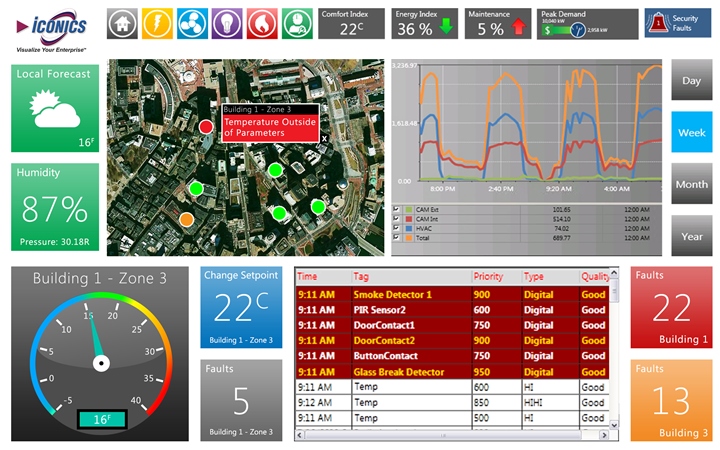

We specialize in graphically

representing the collected data on a

desktop, browser or mobile device to allow building operators and

managers to

optimize their business processes.

|

Melissa Topp

Director of Global Marketing

ICONICS, Inc

|

The

company I work for, ICONICS, has a few decades of experience in the

acquisition, visualization, alarming, trending and, more recently,

in-depth analysis of data; data that mostly came from devices connected

to big industrial equipment performing automated manufacturing tasks.

We specialize in graphically representing the collected data on a

desktop, browser or mobile device to allow operators and managers to

optimize their business processes. They also used that data to analyze

trends over time as well as to notify them with alarms if any part of

the process didn’t follow set parameters.

These prudent uses of both real-time and historical data have provided

enormous cost savings for companies and organizations around the globe

as well as led to a multitude of process improvements. With such

realizations, it was only a matter of time before these concepts found

their way to the building controls industry. Facility managers,

building operators or anyone with responsibility for a physical

location could now apply these same data-driven improvements.

Make Scaling Your Company’s Goal

To draw an analogy from the manufacturing side to the building controls

industry, follow along with this example. For manufacturers, one single

connected device provides the basis for process control. It gets

physically connected to a network, where the control software

recognizes it and can then use its data for graphical representation,

trending, alarming and more. Of course, that device is usually joined

by many others to represent a single process; for example, the

manufacturing process for a single physical item or widget.

So you have a control system for your

manufacturing assembly process in

one floor of your factory. Success and expansion to other product lines

could necessitate connecting all the devices related to the entire

product family. Still, that might just be an additional floor of your

factory and, depending on your software provider, the control software

easily scales. Now let’s say the demand for your product necessitates a

whole additional factory nearby. Scalable control software handles this

easily. Let’s say the company branches out internationally to dozens of

factories across the world. You’re a global enterprise now and,

depending on your software provider, your control software has easily

scaled from those days of single devices to millions of connected tags,

providing the lifeblood of your entire product portfolio: data.

Building Blocks of Facility-based

Savings

Now to relate this example to what ICONICS has achieved on the building

automation and energy management side, there are dozens of different

processes taking place in buildings everywhere day after day. These

include heating, ventilation, air conditioning, lighting, energy

monitoring, physical security, fire safety, elevator use and more.

Similar to the manufacturing example, such processes can start out

small; maybe initially applied to one room in a single building. The

considered usefulness of the data might then warrant expansion out to

an entire floor, then another, then maybe through an entire building.

Additional processes are added in a similar rollout, where the single

building’s use case leads to expansion to an entire campus. It is

possible for such initiatives to get adopted by an entire city or even

country-wide.

Such a scenario is not some delusion of

grandeur. It has been achieved,

and by none other an organization than Microsoft.

Microsoft sought a way to reduce energy

spending at its 500-acre

Redmond, Washington headquarters. An internal team advised against the

company spending $60 million to address the concern and to rather use

commercial, over-the-shelf software. A test run of the team’s plans was

performed within 13 of 125 buildings. The team utilized the selected

control software to tie multiple disparate building management systems

together, providing multiple points of data to analyze. It gave

Microsoft the means to see 30,000 unconnected, sensor-enabled pieces of

equipment as a cohesive whole generating over half a billion data

transactions every single day; but in a way that was easier to manage

and understand.

The data provided to Microsoft’s Redmond Operations Center (ROC) was

enormously valuable, reporting on inefficiencies involving lighting

schedules, air conditioning, heating and more. The test case was soon

rolled out into the entirety of Microsoft’s Redmond campus, now

handling billions of data points to visualize, analyze and improve.

[an error occurred while processing this directive]

In addition to the immediate savings seen due to the selected

software’s energy management capabilities, Microsoft also saw savings

by implementing fault detection and diagnosis (FDD) features, as well.

What FDD provides is the ability to incorporate user customizable fault

rules to weigh the probability of equipment failure and to advise

personnel of immediate preventative actions they can take before faults

occur. When equipment failures occur, the software analyzes current and

historical information along with symptom/cause relationships that the

system has been taught, executes predictive algorithms, and provides

the user guidance with a list of probable causes sorted by probability.

This immediate guidance reduces mean time to diagnose and repair,

reduces equipment downtime, and lowers overall maintenance costs.

For engineers at Microsoft’s Redmond campus this means less time

“climbing over rooftops, inspecting pump rooms and peering above

ceiling tiles” and more time spent proactively where actual problems

could occur, further contributing to cost savings. With combined energy

and FDD analysis capabilities, the company reduced its energy

consumption/costs, extended the life of its building assets, drives

continuous labor efficiencies, and shrunk its carbon footprint.

Microsoft now saves into the millions of dollars annually just at their

Redmond campus, with further rollout planned throughout their worldwide

locations.

About the Author

Melissa Topp is the Director of Global Marketing

for ICONICS, a

world-leading software developer of open standards-based visualization,

HMI/SCADA and enterprise solutions for energy, industrial,

manufacturing and building automation. With more than 300,000

installations worldwide, ICONICS, the Microsoft CityNext and

Sustainability Partner of the Year, helps its customers be more

profitable, agile, efficient and sustainable. Melissa has a B.S. in

Computer Science and Management Information Systems from Worcester

Polytechnic Institute and over 12 years of industry experience.

About

ICONICS

ICONICS, a globally managed Microsoft Gold Partner, 2014 Microsoft

Public Sector CityNext Partner of the Year Award Winner and past

recipient of the Microsoft Sustainability Partner of the Year award,

provides solutions to improve productivity, reduce integration time and

operating costs, and optimize asset utilization with visualization and

automation software. Founded in 1986, ICONICS has 300,000 installations

in over 60 countries worldwide. ICONICS software is recommended for

automating, monitoring and optimizing a customer’s most critical assets

and has been selected by over 70 percent of Fortune 500 companies.

ICONICS meets the demanding application challenges of the automotive,

building automation, food and beverage, government infrastructure,

manufacturing, petrochemical, pharmaceutical, renewable energy,

utilities and water/wastewater industries. As a managed Microsoft ISV

Partner, ICONICS designs its solutions to leverage Microsoft

technologies, including Windows 8, Windows Server 2012, Microsoft .NET,

Windows Azure, SQL Server and Microsoft SharePoint.

footer

[an error occurred while processing this directive]

[Click Banner To Learn More]

[Home Page] [The

Automator] [About] [Subscribe

] [Contact

Us]